Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

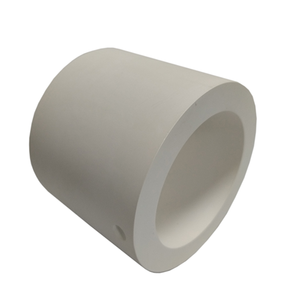

(KERUI 99% Aluminum Alumina Ceramic Corundum Tube Thermocouple Protection For Refractory Applications Fiberglass Moulded)

Specifications of KERUI 99% Aluminum Alumina Ceramic Corundum Tube Thermocouple Protection For Refractory Applications Fiberglass Moulded

The KERUI 99% Aluminum Alumina Ceramic Diamond Tube is made for high-temperature thermocouple defense popular commercial environments. This product uses premium 99% alumina ceramic material. The structure ensures outstanding thermal security and resistance to extreme conditions. It operates effectively in temperature levels as much as 1600 ° C. Television suits applications in steelmaking, glass production, petrochemical handling, and other refractory-heavy markets.

The alumina ceramic structure offers reduced thermal expansion. This lessens breaking under rapid temperature adjustments. The material withstands chemical deterioration from acids, antacid, and molten steels. This extends the tube’s life span in hostile setups. Its high compressive stamina makes sure sturdiness versus mechanical tension. The tube preserves structural integrity also under heavy loads.

A fiberglass-reinforced molding procedure improves television’s durability. This method develops a dense, uniform structure with marginal porosity. The smooth internal surface area lowers contamination dangers for thermocouples. The precision-molded design makes sure regular wall thickness. This improves heat circulation and measurement precision.

The tube supplies excellent electrical insulation. This stops disturbance in temperature analyses. Its light-weight layout simplifies handling and installment. Personalized sizes and diameters are offered to fit details equipment demands. The product incorporates flawlessly with typical thermocouple configurations.

Applications consist of securing sensors in kilns, heaters, central heating boilers, and activators. It shields thermocouples from direct fire direct exposure and rough materials. The tube’s non-reactive homes make it appropriate for food-grade or pharmaceutical home heating procedures. Its reduced thermal conductivity reduces heat loss. This optimizes power efficiency in high-temperature systems.

Regular maintenance is very little due to the product’s wear resistance. Television stands up to oxidation and thermal shock. This decreases downtime in industrial operations. Substitute cycles are longer compared to steel or lower-grade ceramic alternatives.

The KERUI ceramic tube fulfills worldwide standards for refractory products. It undertakes extensive quality testing for thickness, hardness, and thermal efficiency. Each set is evaluated for defects to make sure dependability. The product is packaged securely to stop damage throughout shipping.

Compatibility with numerous thermocouple types enhances its flexibility. Customers can pick setups for Kind K, S, R, or B thermocouples. Technical assistance is readily available for custom remedies. The product is stocked for quick distribution to global consumers.

(KERUI 99% Aluminum Alumina Ceramic Corundum Tube Thermocouple Protection For Refractory Applications Fiberglass Moulded)

Applications of KERUI 99% Aluminum Alumina Ceramic Corundum Tube Thermocouple Protection For Refractory Applications Fiberglass Moulded

The KERUI 99% Aluminum Alumina Porcelain Diamond Tube Thermocouple Defense Tube is designed for high-temperature industrial atmospheres. It operates in refractory applications and fiberglass molding procedures. The tube is made from 99% alumina ceramic. This product ensures exceptional heat resistance. It manages temperature levels up to 1600 ° C without breaking down. The high alumina web content offers solid chemical stability. It stands up to deterioration from acids, antacid, and molten steels. This makes it ideal for severe commercial setups.

The ceramic tube shields thermocouples in severe problems. It guards sensing units from direct exposure to flames, rough materials, and thermal shock. Its dense structure avoids gas infiltration. This expands the life-span of temperature measurement tools. The product is perfect for markets like steelmaking, glass manufacturing, and foundries. It does dependably in kilns, furnaces, and reactors.

Mechanical strength is an essential feature. The tube stands up to fracturing under quick temperature level adjustments. This minimizes downtime in procedures. Its smooth surface lessens accumulation of slag or down payments. Maintenance demands are reduced contrasted to metal options. The product’s high dielectric toughness protects against electrical interference. Precise temperature level readings are ensured.

Installation is uncomplicated. Television fits conventional thermocouple arrangements. Personalized sizes and shapes are offered for particular requirements. It works with various thermocouple types. This flexibility sustains varied commercial configurations.

In fiberglass moulding, the tube secures sensing units during high-heat curing procedures. Accurate temperature level control is critical below. The ceramic’s thermal insulation properties avoid heat loss. This boosts power performance.

The KERUI ceramic tube is a cost-effective service. It lasts longer than typical steel or lower-grade ceramic tubes. Substitute expenses lower. Production effectiveness rises. Industries needing long lasting, high-performance thermocouple security will discover it reliable.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of KERUI 99% Aluminum Alumina Ceramic Corundum Tube Thermocouple Protection For Refractory Applications Fiberglass Moulded

KERUI 99% Aluminum Alumina Ceramic Corundum Tube Thermocouple Protection for Refractory Applications Fiberglass Moulded – FAQs

1. What material is the thermocouple protection tube made of?

The tube uses 99% aluminum alumina ceramic corundum. This material ensures high heat resistance. It works well in extreme temperatures. The structure stays stable under thermal stress. It resists chemical corrosion.

2. What temperature range can the tube handle?

The tube handles up to 1700°C. It suits high-heat industrial settings. It protects thermocouples in furnaces, kilns, or molten metal applications. The ceramic composition prevents melting or warping.

3. Where is this product commonly used?

It is used in refractory environments. Examples include steel plants, glass factories, and cement production. It shields thermocouples in fiberglass moulding processes. It is ideal for harsh, abrasive conditions.

4. How is the tube installed?

The tube is designed for easy installation. Slide the thermocouple into the tube. Secure it using compatible fittings. Ensure the fiberglass-moulded end faces the measurement point. Follow the equipment’s manual for alignment.

5. Does the tube require maintenance?

Minimal maintenance is needed. Inspect it regularly for cracks or wear. Replace it if physical damage is visible. The ceramic material resists most buildup. Clean it with compressed air if debris accumulates.

(KERUI 99% Aluminum Alumina Ceramic Corundum Tube Thermocouple Protection For Refractory Applications Fiberglass Moulded)

REQUEST A QUOTE

RELATED PRODUCTS

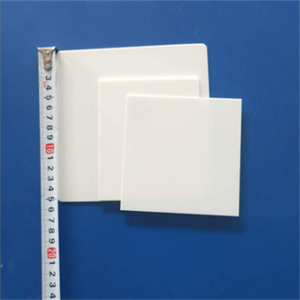

Corrosion Resistance Custom Ceramic 99% Alumina Ceramic Product

Customization Industrial Insulation High Precision High Purity Ceramics 95% 99% 99.5% Structural Parts Alumina Ceramic

Customized OEM 95% 99% 99.5% Al2O3 Alumina Ceramic Insulator Components Parts

Porous Semiconductor Ceramics/insulating Electronic Ceramics/995 Alumina Ceramics

Extruded Pressed Cellular Alumina Honeycomb Ceramic Porous Ceramic