Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

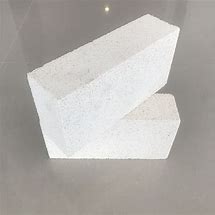

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Precision Ceramic Tubes High Temperature Resistant High Hardness 99% Alumina Ceramic Parts)

Specifications of Precision Ceramic Tubes High Temperature Resistant High Hardness 99% Alumina Ceramic Parts

Precision Ceramic Tubes High Temperature Resistant High Hardness 99% Alumina Ceramic Parts are crafted for requiring industrial applications. These tubes are made from 99% alumina ceramic, guaranteeing extraordinary performance in extreme conditions. The product supplies impressive resistance to heats, dealing with continuous use up to 1650 ° C. This makes them perfect for settings where warmth administration is crucial.

The high hardness of these ceramic tubes ranks them amongst the most difficult industrial materials. They attain a Mohs firmness of 9, 2nd only to ruby. This property decreases wear and extends service life in rough or high-friction settings. Their architectural security continues to be undamaged even under mechanical stress or thermal shock.

These tubes feature exceptional electrical insulation homes. They resist present leakage in high-voltage applications. Their reduced thermal conductivity aids maintain temperature control in systems requiring warm control. The smooth surface area finish lowers rubbing, boosting efficiency in fluid transfer or leading applications.

Chemical resistance is an additional vital benefit. The alumina ceramic composition stands up to corrosion from acids, antacid, and molten steels. This guarantees integrity in chemical handling or metallurgical procedures. The non-porous structure avoids contamination, making them appropriate for semiconductor manufacturing or medical tools.

Dimensional accuracy is guaranteed through advanced manufacturing processes. Tight tolerances fulfill exact requirements for inner/outer sizes and wall thickness. Custom sizes and shapes are readily available to fit specific machinery or systems.

These tubes are extensively made use of in aerospace, energy, and electronic devices sectors. Usual applications include thermocouple protection, furnace linings, and laser parts. They also serve in high-temperature sensors, electric insulators, and lab tools.

Quality control complies with rigorous requirements. Each batch goes through testing for thickness, hardness, and thermal stability. Accreditations make sure compliance with international industrial needs.

The product is available in common sizes or customized designs. Bulk orders get competitive prices and fast preparations. Technical assistance aids with material choice and integration into existing systems.

(Precision Ceramic Tubes High Temperature Resistant High Hardness 99% Alumina Ceramic Parts)

Applications of Precision Ceramic Tubes High Temperature Resistant High Hardness 99% Alumina Ceramic Parts

Accuracy ceramic tubes made from 99% alumina ceramic are engineered for requiring settings. These components master high-temperature settings, withstand extreme mechanical stress and anxiety, and stand up to chemical deterioration. Their solidity places near to rubies, making certain longevity in abrasive conditions. Industries count on these tubes for important applications as a result of their stability and performance.

Industrial furnace use alumina ceramic tubes as thermocouple protection sheaths. The product deals with temperatures over 1600 ° C without breaking down. This prevents sensing unit damages in furnaces or kilns. Semiconductor manufacturing depends upon these tubes for wafer handling. They keep pureness in high-heat chambers, preventing contamination during deposition or etching.

Aerospace and defense markets use alumina tubes in sensors and igniters. The parts sustain quick temperature level changes and mechanical shocks in engines or exhaust systems. Clinical devices integrates ceramic tubes for laser systems and analytical instruments. Their electrical insulation and thermal resistance guarantee secure operation in MRI machines or medical tools.

Chemical handling plants make use of these tubes in pumps and shutoffs. Alumina stands up to acids, alkalis, and solvents, protecting against leaks or corrosion. The smooth surface area minimizes friction in liquid transfer systems. This decreases wear and extends part lifespan.

High-purity alumina ceramic tubes match vacuum environments. They outgas minimally, preserving stress stability in clinical tools or area simulation chambers. Personalized shapes and sizes are attainable via sophisticated molding and sintering. This versatility meets precise demands for specialized machinery.

The mix of high hardness and thermal shock resistance makes these tubes ideal for steel creating. They lead wires or molten metals without buckling. Electric insulation residential properties avoid short circuits in high-voltage applications like insulators or ignition system.

99% alumina ceramic tubes supply reduced thermal development. This makes sure dimensional security throughout quick heating or cooling down cycles. Their non-porous framework resists wetness absorption, crucial for humid or destructive setups. Manufacturers pick these tubes for integrity under anxiety, reducing downtime and upkeep prices.

Cost-effectiveness gradually offsets the first investment. Lengthy service life and marginal substitute requires make them a functional selection. These tubes fulfill strict market standards for accuracy and safety and security, sustaining advanced technologies throughout multiple areas.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Precision Ceramic Tubes High Temperature Resistant High Hardness 99% Alumina Ceramic Parts

What makes these ceramic tubes handle high temperatures?

The tubes use 99% alumina. This material is known for heat resistance. Alumina keeps its shape and strength even at extreme temperatures. The structure stays stable. It does not crack or warp under heat stress. This makes the tubes reliable in hot environments.

Where are these tubes typically used?

They work in high-heat industries. Examples include furnace linings, semiconductor processing, and aerospace parts. They suit labs, metal processing, and chemical plants. These tubes handle harsh conditions. They protect equipment from heat damage.

Why does high hardness matter?

High hardness resists wear and scratches. The tubes last longer in rough conditions. They handle abrasion from powders, chemicals, or friction. This reduces replacements. It cuts downtime and maintenance costs.

Can the tubes be customized?

Yes. Sizes and shapes match specific needs. Common forms are straight or curved tubes. Custom lengths, diameters, and wall thicknesses are possible. Tighter tolerances are available. Production uses advanced molding and machining.

How do I install and maintain these tubes?

Handle them carefully. Avoid impacts or sudden force. Use proper tools for cutting or drilling. Clean with non-abrasive materials. Do not expose to rapid temperature changes. Check for cracks or wear regularly. Replace damaged tubes quickly to prevent failures.

(Precision Ceramic Tubes High Temperature Resistant High Hardness 99% Alumina Ceramic Parts)

REQUEST A QUOTE

RELATED PRODUCTS

95% 99% Ceramic Pipe High Purity Heat Resistance Alumina Ceramic Tube

Al2O3 Ceramic Hot Selling Refractory Alumina Brick Kiln Rotary Kiln Building Making Clay Brick For Oven

Al2O3 Ceramic mutiple size aluminium oxide ceramic tubes

High Quality Steatite Ceramics for Industries Alumina Industrial Ceramics

Wear Resistant Alumina Ceramic Hexagonal Tile 12mm