Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

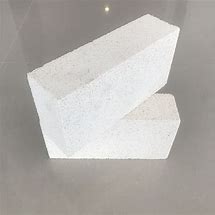

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Thickness 0.635mm to 1mm 99% Al2o3 Alumina Ceramic Substrate Ceramic Plate Zirconia Plate)

Specifications of Thickness 0.635mm to 1mm 99% Al2o3 Alumina Ceramic Substrate Ceramic Plate Zirconia Plate

The product is a high-performance alumina ceramic substrate plate made from 99% Al2O3. It supplies density alternatives ranging from 0.635 mm to 1mm. This material is perfect for applications calling for accuracy, durability, and thermal security. The ceramic plate is crafted for electronic devices, automobile systems, industrial tools, and advanced innovations. Its structure makes sure excellent electrical insulation, high thermal conductivity, and resistance to put on, rust, and extreme temperatures.

The alumina ceramic substratum supplies regular mechanical toughness. It manages high-stress atmospheres without cracking or buckling. The surface coating is smooth, making sure trustworthy performance in circuit card, sensing units, and semiconductor elements. The material’s monotony is snugly controlled to meet strict sector criteria. This makes it appropriate for microelectronics and accuracy design.

Thermal administration is a vital feature. The plate efficiently dissipates warm, preventing getting too hot in high-power devices. It runs stably in temperature levels approximately 1600 ° C. This ability matches applications like LED illumination, power modules, and aerospace systems. The ceramic’s reduced thermal growth reduces danger of thermal mismatch with bonded products.

Electrical insulation residential properties are outstanding. The alumina ceramic withstands high voltages, making it secure for digital circuits and protecting layers. It minimizes energy loss in high-frequency applications. The product’s solidity and use resistance extend product life expectancy in abrasive or high-friction environments.

Zirconia plates are available as an option. They provide greater fracture toughness while keeping similar thermal and electric performance. Both alumina and zirconia plates are adjustable in size, shape, and opening patterns. Laser reducing and precision machining ensure exact dimensions for details project requirements.

Quality assurance procedures include strenuous screening for density, porosity, and dimensional accuracy. Each batch meets worldwide standards for industrial porcelains. Home plates work with thin-film and thick-film metallization processes. This allows very easy assimilation with conductive materials for electronic applications.

Applications span medical tools, telecommunications, energy systems, and vehicle electronics. The material’s chemical inertness makes it immune to acids, antacid, and solvents. It performs dependably in rough or corrosive atmospheres. Custom-made product packaging alternatives are readily available for mass orders or specialized shipping requirements.

(Thickness 0.635mm to 1mm 99% Al2o3 Alumina Ceramic Substrate Ceramic Plate Zirconia Plate)

Applications of Thickness 0.635mm to 1mm 99% Al2o3 Alumina Ceramic Substrate Ceramic Plate Zirconia Plate

The thickness variety of 0.635 mm to 1mm in 99% Al2O3 alumina ceramic substrates and zirconia plates satisfies diverse industrial requirements. These products offer high thermal conductivity, electrical insulation, and mechanical toughness. They manage severe temperatures and rough atmospheres efficiently.

In electronic devices, these ceramic plates function as circuit card or insulation layers. Their slim layout matches small tools like mobile phones or microchips. The 0.635 mm thickness fits high-density circuits. Thicker 1mm plates provide additional toughness for heavy-duty applications. Thermal management advantages LED lights systems. Heat spreads equally, protecting against getting too hot.

The clinical field utilizes alumina ceramic substratums for implants or medical devices. Biocompatibility makes certain safe contact with body cells. Thin plates operate in dental gadgets or bone repair service implants. Zirconia plates, harder than alumina, replace steel parts in joint substitutes. They resist wear and rust.

Automotive systems rely on these ceramics for sensors or engine elements. Oxygen sensing units check exhaust gases. High-temperature security guarantees accuracy in rough conditions. Thicker plates deal with vibration and mechanical stress and anxiety in engine mounts. Electric lorries utilize them in battery insulation. Warmth dissipation protects battery life.

Industrial applications consist of machinery components subjected to abrasion or chemicals. Alumina substrates line pipes or valves in harsh liquid systems. Wear-resistant surfaces extend devices life-span. Zirconia layers cut steel handling devices. Their hardness decreases wear throughout machining.

Zirconia plates vary from alumina. Greater fracture durability matches high-stress duties. They operate in cutting tools or aerospace elements. Alumina remains economical for electrical insulation. Both materials adapt to laser cutting or accuracy machining. Custom shapes fulfill particular project requirements.

These ceramic substrates sustain renewable resource technology. Solar panels use them for insulation layers. Wind generators incorporate porcelains in sensing units. The 0.635 mm to 1mm array balances versatility and toughness. Thin layers decrease weight in aerospace sensing units. Thicker options withstand mechanical lots in industrial equipment.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Thickness 0.635mm to 1mm 99% Al2o3 Alumina Ceramic Substrate Ceramic Plate Zirconia Plate

What are the main uses of 0.635mm to 1mm alumina ceramic plates? These plates work well in electronics, sensors, and heaters. They handle high heat and insulate electricity. Industrial machines use them for wear-resistant parts. Their thin design fits compact devices.

Why choose 99% Al2O3 for ceramic substrates? High-purity alumina boosts strength and insulation. It resists chemicals and lasts longer under stress. This grade suits extreme environments. It keeps performance stable in high temperatures.

How does thickness affect performance? Thinner plates (0.635mm) bend slightly for tight spaces. Thicker plates (1mm) handle heavier loads. The choice depends on heat needs and space limits. Both options stay durable and efficient.

Can these plates survive high temperatures? Yes. They work up to 1600°C. They cool or heat fast without cracking. This makes them ideal for furnaces or aerospace parts.

What’s the difference between zirconia and alumina plates? Zirconia is tougher against impacts. Alumina handles higher heat and insulates better. Pick zirconia for mechanical stress. Pick alumina for extreme temperatures or electrical projects.

(Thickness 0.635mm to 1mm 99% Al2o3 Alumina Ceramic Substrate Ceramic Plate Zirconia Plate)

REQUEST A QUOTE

RELATED PRODUCTS

99% Alumina Ceramic Plate for Semiconductor/Medical/Electronics, High Purity, Wear Resistant, Insulating

Square / Hexagon Al2o3 Alumina Ceramic Tiles and Plates

Ceramic C795 95% Alumina Ceramic Top Smoking Rolling Smoking Accessories

Customizable High-precision Colored Industrial Ceramics.Alumina Ceramic.zirconia Ceramic

Al2O3 Ceramic Hot Selling Refractory Alumina Brick Kiln Rotary Kiln Building Making Clay Brick For Oven