Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Wear Resistance 95% Alumina Ceramic Rods For Knife Sharpening)

Specifications of Wear Resistance 95% Alumina Ceramic Rods For Knife Sharpening

Wear Resistance 95% Alumina Ceramic Rods for Blade Developing deal a resilient service for keeping sharp edges on blades. These poles are made from high-purity alumina ceramic, consisting of 95% aluminum oxide. The material ensures phenomenal hardness, placing 9 on the Mohs scale. This residential property makes them immune to wear, even with regular usage. The rods maintain their shape with time, avoiding deformation under pressure. Their surface area includes a great abrasive texture, developed to hone blades without creating excessive damage. The appearance removes very little steel from the blade, maintaining its integrity while restoring intensity.

The poles come in standard sizes of 15mm, 20mm, and 25mm. Length options consist of 150mm, 200mm, and 250mm. This variety accommodates various blade sizes and customer preferences. The ceramic product is non-porous, avoiding absorption of oils or wetness. This high quality makes certain health and simple cleansing. A fast rinse with water or clean with a towel eliminates particles. The poles withstand discoloration, keeping a tidy look after repeated use.

High thermal security enables these rods to endure temperature levels up to 1600 ° C. They carry out accurately in both high-heat and low-temperature environments. Chemical resistance protects against acids, antacid, and solvents. This makes them ideal for commercial settings or severe cleansing procedures. The alumina ceramic structure protects against rust, ensuring long-term functionality.

The rods benefit honing cooking area blades, hunting blades, and accuracy tools. They work with stainless-steel, carbon steel, and ceramic blades. Customers take advantage of consistent results, achieving sharp sides with marginal effort. The light-weight style lowers hand tiredness throughout extended use. A smooth, ergonomic grip improves control, boosting safety throughout sharpening.

Setup is basic. The poles match typical developing pole holders or can be used portable. No special maintenance is required. Storage in a dry atmosphere stops unintended damages. Prevent dropping the rods, as abrupt influences may trigger cracking. Proper handling ensures years of reliable efficiency.

These alumina ceramic rods are an effective upgrade from typical honing devices. They integrate advanced material scientific research with sensible layout. Individuals gain a device that develops efficiently, lasts much longer, and adapts to varied demands.

(Wear Resistance 95% Alumina Ceramic Rods For Knife Sharpening)

Applications of Wear Resistance 95% Alumina Ceramic Rods For Knife Sharpening

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Wear Resistance 95% Alumina Ceramic Rods For Knife Sharpening

What makes 95% alumina ceramic rods good for knife sharpening?

The high alumina content gives these rods extreme hardness. They resist wear better than steel or lower-grade ceramics. This hardness lets them sharpen blades without wearing down quickly. The smooth surface aligns knife edges evenly. It removes tiny metal burrs without damaging the blade.

How do I use alumina ceramic rods to sharpen knives?

Hold the rod steady on a flat surface. Slide the knife edge along the rod at a 15-20 degree angle. Apply light pressure. Repeat 5-10 times per side. Clean the rod after use. Avoid pressing too hard. This prevents uneven sharpening or blade damage.

Do these rods need regular maintenance?

They require minimal upkeep. Wipe them with a damp cloth to remove metal particles. Use mild soap if needed. No oil or special treatments are necessary. Store them in a dry place. Chips or cracks are rare but replace the rod if they appear.

How long do alumina ceramic rods last compared to other materials?

They outlast most steel rods. The 95% alumina composition resists wear for years. Steel rods groove over time. Ceramic stays smooth. With proper care, one rod can handle daily sharpening for 5-10 years.

Can these rods work on all knife types?

They suit most steel knives. Ceramic or serrated blades may not benefit. Harder steels like Japanese knives sharpen well. Softer steels work too. Test on a small section first. Avoid using on brittle blades.

(Wear Resistance 95% Alumina Ceramic Rods For Knife Sharpening)

REQUEST A QUOTE

RELATED PRODUCTS

Wear Resistant Alumina Ceramic Hexagonal Tile 12mm

Al2O3 Ceramic mutiple size aluminium oxide ceramic tubes

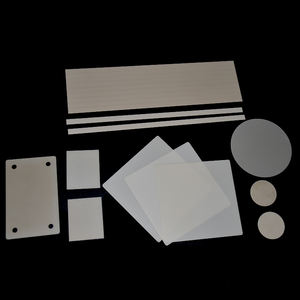

Al2o3 High Precision 95 99 Ceramic Plate Wear Resistant Alumina Ceramic Plate

Al2o3 Crucible Alumina Ceramic High Refractoriness Alumina Al2O3 Ceramic Crucible

Porous Semiconductor Ceramics/insulating Electronic Ceramics/995 Alumina Ceramics