Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

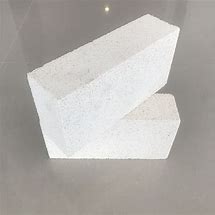

(Wear-resistant Alumina Ceramic Sheets Industrial Wear-resistant Ceramics Alumina Ceramics)

Specifications of Wear-resistant Alumina Ceramic Sheets Industrial Wear-resistant Ceramics Alumina Ceramics

Wear-resistant alumina ceramic sheets provide sturdy remedies for markets handling hefty abrasion and mechanical wear. These ceramics excel in harsh environments like mining, cement manufacturing, and steel production. The material consists of 92-95% aluminum oxide, making certain high solidity and resistance to surface area damage. Its portable framework minimizes particle penetration, prolonging life span in unpleasant problems.

The sheets include a smooth surface, minimizing friction against machinery components. This decreases energy consumption and protects against product accumulation. High-temperature stability allows consistent performance up to 1600 ° C without splitting. Chemical inertness shields against acids, alkalis, and corrosive compounds. This makes the porcelains ideal for chemical handling and power generation sectors.

Mechanical toughness is a vital advantage. The sheets stand up to heavy influence and pressure, maintaining integrity under load. Compressive strength surpasses 2200 MPa, outshining lots of metals. Installment options consist of epoxy adhesives or mechanical bolts, guaranteeing protected add-on to devices surfaces. Customized shapes and sizes are offered to fit certain equipment like pipes, chutes, or hoppers.

Alumina porcelains decrease downtime by lasting longer than traditional steel components. They withstand contortion and wear, reducing replacement regularity. Price financial savings originated from reduced maintenance and enhanced devices effectiveness. Lightweight properties alleviate managing and installment contrasted to metal alternatives.

The sheets function well in bulk material handling systems. They protect devices from erosion brought on by coal, ore, or sand. In thermal plants, they shield ducts and cyclones from ash abrasion. Versatility allows use in pumps, shutoffs, and followers exposed to slurry or dust.

Personalized density arrays from 5mm to 30mm, stabilizing wear resistance and weight. Surface area surfaces can be readjusted for particular rubbing demands. Pre-engineered mosaic formats streamline large-area insurance coverage. Interlacing styles protect against spaces, making sure full protection.

Wear-resistant alumina ceramics enhance operational integrity across markets. Their mix of hardness, thermal security, and chemical resistance addresses usual wear obstacles. By integrating these sheets, services improve equipment long life and reduce manufacturing prices.

(Wear-resistant Alumina Ceramic Sheets Industrial Wear-resistant Ceramics Alumina Ceramics)

Applications of Wear-resistant Alumina Ceramic Sheets Industrial Wear-resistant Ceramics Alumina Ceramics

Wear-resistant alumina ceramic sheets are widely utilized in sectors where tools deals with extreme conditions. These porcelains secure machinery from damages triggered by rubbing, effect, and chemical exposure. Their high hardness and resilience make them optimal for expanding the service life of industrial elements.

In mining procedures, alumina porcelains line tools like conveyor belts, chutes, and receptacles. They stop abrasion from heavy ore and minerals. This minimizes downtime and upkeep expenses. Steel plants utilize these ceramics in blast furnaces and rolling mills. The sheets withstand extreme temperature levels and slag erosion. This keeps production lines running efficiently.

Cement production depends on alumina ceramics for crushers, kilns, and grinders. The material stands up to consistent grinding from basic materials. It preserves architectural stability even under high stress and anxiety. Power plants use these sheets to coal-handling systems. They minimize use from rough coal bits. This guarantees effective power generation.

Chemical processing sectors benefit from alumina porcelains in pumps, shutoffs, and activators. The product withstands deterioration from acids and alkalis. It makes certain safe handling of hostile substances. Alumina porcelains are likewise utilized in aerospace and automobile fields. They shield components from warm and put on in engines and wind turbines.

The crucial benefit of alumina porcelains is their phenomenal hardness. They rate simply below diamonds on the Mohs scale. This property makes them last much longer than steels or polymers. Their low weight lowers stress on equipment. They are very easy to install and replace. Personalized shapes and sizes fit details equipment demands.

Alumina porcelains keep efficiency in temperatures as much as 1600 ° C. They do not break or warp under thermal anxiety. Electric insulation residential or commercial properties protect against brief circuits in high-voltage atmospheres. The non-reactive surface area prevents contamination in food or pharmaceutical applications.

Cost cost savings come from decreased part replacements and upkeep. Industries report longer equipment life and greater efficiency. Alumina ceramic sheets are a useful remedy for challenging environments. They stabilize efficiency with economic effectiveness.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Wear-resistant Alumina Ceramic Sheets Industrial Wear-resistant Ceramics Alumina Ceramics

Wear-resistant alumina ceramic sheets are industrial ceramics designed for heavy-duty applications. Here are five common questions about them. What are these ceramic sheets made of? They are made from high-purity aluminum oxide. The material is processed under high heat to form a dense structure. This gives the sheets extreme hardness and durability. The alumina content usually ranges between 92% and 99%. Higher alumina percentages improve wear resistance and strength.

How do alumina ceramics resist wear? The hardness of alumina ranks just below diamonds on the Mohs scale. This makes the sheets highly resistant to abrasion and scratching. They handle constant friction from materials like coal, ore, or sand. Their smooth surface reduces material buildup. The structure stays stable even under high-stress conditions.

Where are these ceramics typically used? They are common in mining, power plants, and cement industries. Equipment like chutes, hoppers, and pipelines face heavy wear. Alumina linings protect these parts. They are also used in steel mills and chemical plants. Any machinery exposed to abrasive materials benefits from these sheets.

How are the ceramic sheets installed? They are fixed using bolts, adhesives, or welding. Bolt-on panels allow easy replacement. Adhesives bond sheets to metal surfaces for seamless coverage. Welding is used for high-temperature environments. Proper installation ensures maximum contact with the protected surface. Gaps or uneven fitting reduce effectiveness.

What sizes and shapes are available? Standard sizes include rectangles, squares, and trapezoids. Thickness ranges from 5mm to 30mm. Custom shapes can be made to fit specific machinery. Curved or interlocking designs suit complex surfaces. Pre-drilled holes simplify installation. Manufacturers often provide templates for precise fitting.

Why choose alumina over other wear-resistant materials? Alumina lasts longer than steel or rubber in abrasive settings. It resists corrosion from chemicals and moisture. The lightweight nature reduces strain on equipment. Maintenance costs drop due to less frequent replacements. Energy consumption stays low because of smooth material flow.

(Wear-resistant Alumina Ceramic Sheets Industrial Wear-resistant Ceramics Alumina Ceramics)

REQUEST A QUOTE

RELATED PRODUCTS

Industrial High Purity High Temperature Resistance 99% Alumina Ceramic Structural Component

Customization Industrial Insulation High Precision High Purity Ceramics 95% 99% 99.5% Structural Parts Alumina Ceramic

Industrial Electrical Technical Machinery Custom High Heat Resistant Ceramics Alumina Structural Parts

High Heat Resistance High Precision High Strength Alumina Zirconia Ceramic Rod Plunger Piston Tube

High Temperature Alumina Ceramic And Temperature Resistant For Alumina Ceramic Tube