Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction of Boron Carbide Ceramics

Boron carbide ceramics is an inorganic, non-metallic material with carbon and boron as its main components, and its chemical formula is B4C. Since its discovery in the early 20th century, this material has attracted a great deal of attention because of its unique physical and chemical properties. Boron carbide ceramics have an extremely high hardness, second only to diamond and cubic boron nitride, which makes it important in the field of wear-resistant materials. It also exhibits excellent corrosion resistance, high-temperature stability and low-density properties, attributes that make it ideal for the manufacture of bullet-proof vests, nozzles, bearings and other mechanical components that require high wear resistance. Boron carbide ceramics can also be prepared in a variety of shapes and sizes through different processes to meet the needs of different industries.

Characteristics of Boron Carbide Ceramics

Boron carbide ceramics are known for their excellent performance characteristics, starting with their ultra-high hardness and strength, which makes them resistant to severe abrasion and scratching, making them ideal for use in cutting tools and abrasives. Secondly, the material possesses excellent chemical stability and is less likely to react with chemicals such as acids and alkalis, even in extreme environments, making it widely used in certain key components in the chemical industry. In addition, the superior thermal stability of boron carbide ceramics and their ability to maintain structural and property stability at extremely high temperatures makes them one of the key materials in the aerospace and nuclear industries. Finally, it is worth mentioning its lightweight properties, which, due to its low density, make boron carbide ceramics an ideal option for application scenarios that require light weight but high strength. Together, these characteristics give boron carbide ceramics a wide range of applications.

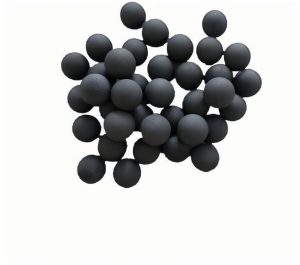

(High Purity B4C Boron Carbide Ceramic Grinding Balls)

Specification of High Purity B4C Boron Carbide Ceramic Grinding Balls

High Pureness B4C Boron Carbide Ceramic Grinding Rounds are developed for accuracy grinding applications. These spheres are made from boron carbide, a product known for severe firmness. The composition makes certain high wear resistance. The purity level surpasses 99.5%, minimizing contamination during handling. This makes them excellent for sensitive atmospheres like research laboratories or modern manufacturing.

Offered sizes vary from 1mm to 50mm. Personalized dimensions can be produced to fulfill particular needs. The spheres include a Vickers solidity of over 30 GPa, rating them amongst the hardest products readily available. This residential property lowers wear throughout extended use. Their thickness is roughly 2.52 g/cm SIX, balancing resilience with convenient weight.

Boron carbide resists chemical rust. It stays stable in acidic or alkaline conditions. This ensures long-term efficiency without deterioration. The material also endures heats, keeping structural integrity up to 600 ° C. Thermal shock resistance prevents fracturing under rapid temperature changes.

These grinding balls are made use of in sectors needing great fragment processing. Examples include aerospace, electronic devices, and progressed ceramics. They function successfully in ball mills, attritors, and vibratory mills. Applications reach grinding unpleasant products like silicon carbide, tungsten carbide, or rare planet steels.

The smooth surface finish decreases rubbing during procedure. This decreases energy intake. Consistent shape and size distribution ensure consistent grinding results. Batch-to-batch top quality is firmly regulated to guarantee dependability.

High purity boron carbide grinding balls minimize contamination threats in crucial procedures. They outmatch options like stainless steel or alumina. Their lifespan exceeds traditional products, lowering substitute expenses. Minimal upkeep is required as a result of their robust nature.

These spheres are suitable for both damp and completely dry grinding. They work with natural solvents and water-based services. Packaging alternatives include vacuum-sealed bags or moisture-resistant containers. Custom labeling and mass orders are sustained.

Industries prioritizing precision and performance advantage most from this product. Their use boosts product top quality in semiconductor manufacturing, progressed optics, and clinical tool production. Performance is validated in high-stress settings, making certain regular output.

(High Purity B4C Boron Carbide Ceramic Grinding Balls)

Applications of High Purity B4C Boron Carbide Ceramic Grinding Balls

High pureness B4C boron carbide ceramic grinding spheres are widely used in markets calling for precision grinding and high wear resistance. Their severe hardness makes them perfect for refining tough products. These grinding balls function well in sphere mills and grinding equipment. They minimize contamination during product processing. This is critical in applications where product purity issues.

In products science and research study laboratories, boron carbide grinding rounds help prepare advanced porcelains, composites, and coatings. They grind raw powders to great, uniform particles. This ensures regular high quality in end products. Their chemical security stops responses with most materials. This keeps processed products devoid of impurities.

The pharmaceutical market makes use of these grinding rounds to create fine powders for medications. They keep stringent hygiene requirements. Their wear-resistant residential or commercial properties lessen bit shedding. This prevents unwanted ingredients in pharmaceutical products. They additionally run successfully in high-speed grinding processes.

Electronics producing relies upon boron carbide grinding spheres for processing materials like silicon and germanium. These products form the basis of semiconductors and digital elements. The grinding rounds’ high purity avoids introducing foreign components. This protects the electric buildings of delicate materials.

Mining and metallurgy take advantage of boron carbide grinding balls in ore grinding and metal removal. They hold up against abrasive environments better than steel or other ceramic media. Their low density lowers energy consumption throughout procedure. This lowers costs in large-scale processing. They also withstand corrosion in acidic or alkaline problems.

Chemical handling plants make use of these grinding balls for mixing and grinding responsive substances. They handle hostile chemicals without weakening. This expands tools lifespan. Their resilience cuts downtime for maintenance.

High pureness B4C grinding spheres are chosen for their efficiency in severe conditions. They provide lengthy life span and reliability. Industries prioritize them for tasks demanding accuracy, tidiness, and efficiency. Their convenience makes them a useful remedy throughout numerous fields.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Purity B4C Boron Carbide Ceramic Grinding Balls

What is B4C boron carbide ceramic?

B4C boron carbide ceramic is a synthetic material made from boron and carbon. It has extreme hardness, high wear resistance, chemical stability. It ranks third in hardness after diamond and cubic boron nitride. These properties make it ideal for grinding applications requiring precision durability.

Why choose B4C grinding balls over other materials?

B4C grinding balls outperform metals, alumina, zirconia in harsh conditions. They resist wear better, last longer. They do not react with acids, alkalis, organic solvents. Their high density improves grinding efficiency. They minimize contamination in sensitive processes like lab research, semiconductor production.

What industries use B4C ceramic grinding balls?

They are common in mining, coatings, electronics, aerospace. They grind pigments, ceramics, metals, advanced powders. Labs use them for sample preparation. Semiconductor makers rely on them for polishing high-purity materials. Their reliability suits heavy-duty and precision tasks.

How to maintain B4C grinding balls?

Clean them regularly with water or mild solvents. Avoid abrasive cleaners. Check for cracks, chips before reuse. Store them dry to prevent moisture buildup. Proper handling extends lifespan. Replace worn balls to maintain grinding consistency.

Can B4C grinding balls be customized?

Yes. Sizes range from 1mm to 50mm. Custom sizes, purity levels, surface finishes are available. High-purity grades (over 99%) suit ultra-clean processes. Discuss needs with suppliers for tailored solutions.

(High Purity B4C Boron Carbide Ceramic Grinding Balls)

REQUEST A QUOTE

RELATED PRODUCTS

Hot Pressing Sintered B4C Boron Carbide Pressureless Sintering Ceramic Parts

Hot Press Sintered Boron Carbide B4C Ball Boron Carbide Ceramic Protective Ball

High Purity B4C Boron Carbide Ceramic Grinding Balls

Black Boron Carbide Micro-powder for Manufacturing Ceramic Products