Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction of Boron Carbide Ceramics

Boron carbide ceramics is an inorganic, non-metallic material with carbon and boron as its main components, and its chemical formula is B4C. Since its discovery in the early 20th century, this material has attracted a great deal of attention because of its unique physical and chemical properties. Boron carbide ceramics have an extremely high hardness, second only to diamond and cubic boron nitride, which makes it important in the field of wear-resistant materials. It also exhibits excellent corrosion resistance, high-temperature stability and low-density properties, attributes that make it ideal for the manufacture of bullet-proof vests, nozzles, bearings and other mechanical components that require high wear resistance. Boron carbide ceramics can also be prepared in a variety of shapes and sizes through different processes to meet the needs of different industries.

Characteristics of Boron Carbide Ceramics

Boron carbide ceramics are known for their excellent performance characteristics, starting with their ultra-high hardness and strength, which makes them resistant to severe abrasion and scratching, making them ideal for use in cutting tools and abrasives. Secondly, the material possesses excellent chemical stability and is less likely to react with chemicals such as acids and alkalis, even in extreme environments, making it widely used in certain key components in the chemical industry. In addition, the superior thermal stability of boron carbide ceramics and their ability to maintain structural and property stability at extremely high temperatures makes them one of the key materials in the aerospace and nuclear industries. Finally, it is worth mentioning its lightweight properties, which, due to its low density, make boron carbide ceramics an ideal option for application scenarios that require light weight but high strength. Together, these characteristics give boron carbide ceramics a wide range of applications.

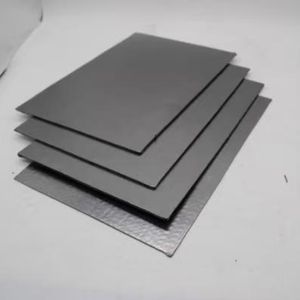

(Silicon Carbide Ceramic Boron Carbide Ceramic Plate B4C Ceramic Tiles Single-curved Surface)

Specification of Silicon Carbide Ceramic Boron Carbide Ceramic Plate B4C Ceramic Tiles Single-curved Surface

Silicon Carbide Ceramic Boron Carbide Porcelain Plates (B4C Porcelain Tiles) with single-curved surface areas are sophisticated design materials designed for extreme problems. These plates combine silicon carbide (SiC) and boron carbide (B4C), offering high hardness, wear resistance, and thermal security. They do well in high-temperature, destructive, or high-impact atmospheres.

Home plates are made from sintered ceramics. Silicon carbide provides outstanding oxidation resistance and thermal conductivity. Boron carbide adds ultra-high hardness, rating simply below ruby. Together, they develop a product that endures abrasion, chemical exposure, and mechanical anxiety.

These ceramic plates can be found in single-curved forms. The bent layout enhances fitment in applications requiring contoured surfaces. Usual usages include shield systems, industrial nozzles, and wear-resistant cellular linings. The curvature makes certain even fill distribution, reducing stress and anxiety factors.

Requirement density varies from 5mm to 30mm. Personalized dimensions are offered. Home plates can be machined to particular resistances for accuracy applications. Surface finishes vary from harsh to polished, depending on usage.

High-temperature resistance reaches 1600 ° C for silicon carbide and 2200 ° C for boron carbide. This makes them ideal for heating systems, aerospace components, and molten steel handling. Low thermal expansion stops splitting under quick temperature modifications.

The products withstand acids, antacid, and salts. They are optimal for chemical processing equipment. Electric insulation buildings add worth in digital or high-voltage settings.

Single-curved B4C ceramic tiles are lightweight compared to metals. This advantages weight-sensitive applications like body shield or air travel. Their density varies between 2.5 g/cm two and 3.2 g/cm four, balancing strength and portability.

Installment utilizes adhesives or mechanical fasteners. Pre-drilled holes simplify mounting. Home plates are compatible with steels, polymers, and compounds.

Testing includes hardness checks (Vickers range), effect resistance tests, and thermal biking. Quality qualifications ensure uniformity. Custom-made forms and hybrid make-ups (SiC-B4C blends) are available.

These ceramic plates are made use of in protection, mining, power, and production. They prolong equipment life expectancy, lower downtime, and enhance safety. Performance remains steady under prolonged stress and anxiety.

The item is readily available around the world. Technical support helps with material choice and style. Examples can be provided for testing. Lead times differ based on order dimension and modification.

(Silicon Carbide Ceramic Boron Carbide Ceramic Plate B4C Ceramic Tiles Single-curved Surface)

Applications of Silicon Carbide Ceramic Boron Carbide Ceramic Plate B4C Ceramic Tiles Single-curved Surface

Silicon carbide ceramic and boron carbide ceramic plates are sophisticated materials used in demanding environments. These ceramics supply high firmness, exceptional thermal resistance, and strong wear resistance. B4C ceramic floor tiles with single-curved surface areas incorporate these residential properties with a form created for specific industrial applications.

These materials are ideal for shield systems. Boron carbide plates are typically utilized in body shield and automobile protection. They quit high-velocity projectiles efficiently. The single-curved style boosts protection and fit on complicated surfaces. This minimizes voids in protective equipment.

Industrial machinery benefits from silicon carbide porcelains. They deal with extreme warmth and destructive chemicals. Components like seals, bearings, and nozzles last longer with these ceramics. The bent surface areas enable installment in tight rooms. This makes certain machinery runs smoothly under rough conditions.

Aerospace and vehicle industries utilize these porcelains for high-performance components. Silicon carbide holds up against extreme warmth in engine parts and turbine blades. Boron carbide ceramic tiles shield delicate devices from abrasion and impact. Bent ceramic tiles fit wind resistant surface areas. This boosts effectiveness in airplane and race cars.

Atomic energy relies on boron carbide for neutron absorption. B4C plates and floor tiles are used in control rods and reactor shielding. The curved style adapts to reactor geometries. This enhances safety and accuracy in nuclear operations.

These porcelains are chosen for toughness and low upkeep. They withstand fracturing under tension and thermal shock. Their long life span lowers substitute costs. Industries prioritize them for critical applications where failing is not an option.

Adjustable single-curved B4C floor tiles fulfill one-of-a-kind job demands. Designers develop them for precise specifications. This flexibility sustains development in defense, energy, and manufacturing sectors.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Silicon Carbide Ceramic Boron Carbide Ceramic Plate B4C Ceramic Tiles Single-curved Surface

What materials are Silicon Carbide Ceramic Boron Carbide Ceramic Plates made of?

These plates combine silicon carbide (SiC) and boron carbide (B4C). Both materials are advanced ceramics known for high hardness and heat resistance. They are processed under extreme conditions to form dense, durable tiles. The single-curved surface design helps fit specific shapes while maintaining structural strength.

Where are B4C Ceramic Tiles commonly used?

These tiles are ideal for armor systems, industrial wear parts, and high-temperature equipment. They protect against abrasion, impact, and extreme heat. Industries like aerospace, defense, and manufacturing rely on them for critical applications. The curved surface allows use in cylindrical or rounded components.

What benefits do these ceramic plates offer over traditional materials?

They outperform metals and standard ceramics in hardness and wear resistance. Boron carbide is one of the hardest materials available. Silicon carbide resists thermal shock better than most ceramics. Both materials last longer in harsh environments. This reduces replacement costs and downtime.

How do Silicon Carbide and Boron Carbide differ in performance?

Boron carbide (B4C) is harder and lighter than silicon carbide (SiC). It is better for stopping high-velocity projectiles. Silicon carbide handles higher temperatures and thermal cycling better. Choosing between them depends on the application’s priorities: B4C for hardness, SiC for heat management.

How are these ceramic plates installed and maintained?

Installation requires bonding with high-strength epoxy or mechanical fasteners. The curved surface must align precisely with the component’s shape. Cutting or drilling needs diamond-tipped tools due to the material’s hardness. Clean surfaces with mild detergents. Avoid abrasive cleaners. Regular inspections check for cracks or wear.

(Silicon Carbide Ceramic Boron Carbide Ceramic Plate B4C Ceramic Tiles Single-curved Surface)

REQUEST A QUOTE

RELATED PRODUCTS

Customized High Anti-Impact Alumina Ballistic Ceramic Armor Plate Boron Carbide Square Patterns Industrial Use Welding Cutting

Whole B4C Boron Carbide Ceramic Tile for Protective Equipment High Hardness Hexagonal Protection Plate

Customized Hexagon Boron Carbide Ceramic Plate B4C Ceramic Tile

High Hardness B4C Boron Carbide Ceramic Tube

Boron Carbide Nozzle Wear Resistant Irregular B4C Ceramic Tube