Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction of Boron Carbide Ceramics

Boron carbide ceramics is an inorganic, non-metallic material with carbon and boron as its main components, and its chemical formula is B4C. Since its discovery in the early 20th century, this material has attracted a great deal of attention because of its unique physical and chemical properties. Boron carbide ceramics have an extremely high hardness, second only to diamond and cubic boron nitride, which makes it important in the field of wear-resistant materials. It also exhibits excellent corrosion resistance, high-temperature stability and low-density properties, attributes that make it ideal for the manufacture of bullet-proof vests, nozzles, bearings and other mechanical components that require high wear resistance. Boron carbide ceramics can also be prepared in a variety of shapes and sizes through different processes to meet the needs of different industries.

Characteristics of Boron Carbide Ceramics

Boron carbide ceramics are known for their excellent performance characteristics, starting with their ultra-high hardness and strength, which makes them resistant to severe abrasion and scratching, making them ideal for use in cutting tools and abrasives. Secondly, the material possesses excellent chemical stability and is less likely to react with chemicals such as acids and alkalis, even in extreme environments, making it widely used in certain key components in the chemical industry. In addition, the superior thermal stability of boron carbide ceramics and their ability to maintain structural and property stability at extremely high temperatures makes them one of the key materials in the aerospace and nuclear industries. Finally, it is worth mentioning its lightweight properties, which, due to its low density, make boron carbide ceramics an ideal option for application scenarios that require light weight but high strength. Together, these characteristics give boron carbide ceramics a wide range of applications.

(Wear Resistant Boron Carbide Ceramic Tile B4C Ceramic Industrial Plate)

Specification of Wear Resistant Boron Carbide Ceramic Tile B4C Ceramic Industrial Plate

Wear-resistant boron carbide ceramic floor tile (B4C ceramic industrial plate) is a high-performance product designed for severe industrial environments. It uses phenomenal resilience and hardness, making it optimal for applications requiring resistance to abrasion, effect, and deterioration. The product is extensively utilized in mining, aerospace, power, and protection markets due to its special properties.

Boron carbide (B4C) is the primary part, known as one of the hardest materials around the world, 2nd just to diamond and cubic boron nitride. Its firmness rises to 9.3 Mohs, giving superior defense versus wear in extreme conditions. The thickness of B4C ceramic floor tiles varies in between 2.45 and 2.55 g/cm FOUR, making certain light-weight yet durable performance contrasted to typical metals.

The floor tiles hold up against temperature levels approximately 600 ° C in oxidizing atmospheres and 2200 ° C in inert ambiences. This thermal security enables use in high-heat settings like heating system linings or protective parts in equipment. The reduced thermal expansion coefficient minimizes form deformation under temperature fluctuations, preserving structural integrity.

B4C ceramic plates display outstanding chemical resistance. They resist acids, alkalis, and destructive substances, making them appropriate for chemical handling equipment or pipes. The material’s non-reactive nature ensures long-lasting reliability in aggressive environments.

Mechanical strength is another crucial function. The compressive stamina surpasses 2800 MPa, making it possible for the ceramic tiles to manage hefty lots without cracking. Their fracture strength is lower than metals, however progressed manufacturing strategies like hot pushing or sintering improve their resistance to chipping and damage.

Modification alternatives include differing densities (5– 30 mm), sizes, and forms to fit details equipment or surfaces. Surface area finishes can be changed for smooth or textured profiles, enhancing grip or decreasing friction as needed.

Installment methods involve bonding the tiles to substrates making use of high-strength adhesives or mechanical bolts. This makes sure safe and secure attachment in high-vibration or high-stress areas.

B4C ceramic floor tiles decrease upkeep costs by prolonging tools life expectancy. They reduce downtime in industries such as mineral handling, where unpleasant materials cause rapid wear. Ballistic protection is one more important application, with the floor tiles used in armor systems due to their capacity to soak up and dissipate influence power.

The product’s lightweight nature decreases transportation and managing costs. It improves performance in applications where weight reduction is important, such as aerospace components or wearable protective gear. Ecological resistance makes sure constant performance in moist, salted, or dusty conditions.

Production procedures prioritize precision to ensure uniformity in density and firmness. Quality assurance steps consist of ultrasonic screening and X-ray evaluation to discover internal problems. This makes sure every floor tile fulfills industry criteria for reliability and security.

(Wear Resistant Boron Carbide Ceramic Tile B4C Ceramic Industrial Plate)

Applications of Wear Resistant Boron Carbide Ceramic Tile B4C Ceramic Industrial Plate

Wear-resistant boron carbide ceramic tiles (B4C) are sophisticated commercial products developed for severe atmospheres. Known for exceptional solidity and resilience, they exceed conventional products like steel and tungsten carbide. These ceramic tiles take care of high-stress applications, making them essential in sectors where wear resistance is critical.

Boron carbide ceramic tiles excel in mining and mineral processing. They line tools such as nozzles, chutes, and pipes exposed to unpleasant materials. Their hardness decreases wear from sand, gravel, and ores. This prolongs tools life, reducing downtime and upkeep costs.

In aerospace and defense, B4C tiles function as light-weight shield. They protect cars and employees from bullets and shrapnel. Their high strength-to-weight ratio makes them optimal for airplane and body armor. These floor tiles withstand effect without including excessive weight, boosting flexibility and safety and security.

The automobile market utilizes boron carbide floor tiles in brake systems and engine elements. They endure heats and friction, ensuring trusted performance in auto racing and sturdy lorries. Their wear resistance minimizes component replacement regularity, lowering long-lasting expenses.

Chemical plants benefit from B4C tiles in pumps, shutoffs, and activators. They stand up to deterioration from acids and antacid, keeping architectural honesty in extreme chemical atmospheres. This dependability avoids leaks and tools failing, supporting constant operations.

Power generation facilities use boron carbide tiles in wind turbines and grinding systems. They endure disintegration from coal ash and other particulates, guaranteeing effective power manufacturing. Their durability minimizes maintenance interruptions, improving plant performance.

Boron carbide floor tiles are additionally used in accuracy machinery. They protect reducing tools and bearings from wear, ensuring precision in manufacturing. This extends device life expectancy, boosting manufacturing efficiency and item top quality.

These floor tiles are functional, adjusting to custom shapes and sizes. Designers integrate them into existing systems without significant redesigns. Their mix of solidity, lightness, and chemical security makes them a practical solution for industries prioritizing resilience and performance.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Wear Resistant Boron Carbide Ceramic Tile B4C Ceramic Industrial Plate

What is boron carbide ceramic tile used for?

Boron carbide ceramic tile is mainly used in industries needing high wear resistance. It protects equipment from abrasion, impact, and erosion. Common applications include mining machinery, bulletproof armor, nozzles, and liners for pumps or chutes. Its hardness makes it ideal for harsh environments with heavy wear.

Why choose boron carbide over other ceramics?

Boron carbide is one of the hardest materials available. It outperforms metals and other ceramics in resisting wear and corrosion. It is lighter than steel and maintains strength at high temperatures. This material also resists acids and alkalis better than alternatives like alumina or silicon carbide.

How are boron carbide tiles installed?

Installation methods depend on the equipment and use case. Tiles are often glued using high-strength epoxy or bonded mechanically with bolts. Surface preparation is critical to ensure adhesion. Professional installation is recommended to avoid cracks or misalignment during fitting.

How do I maintain boron carbide tiles?

Maintenance is minimal due to the material’s durability. Regular cleaning removes debris that might accelerate wear. Inspect tiles periodically for cracks or loose fittings. Damaged tiles should be replaced quickly to prevent further equipment damage. Avoid sudden temperature changes to prevent thermal stress.

What sizes and shapes are available?

Boron carbide tiles come in standard sizes like squares, rectangles, or custom-cut shapes. Thickness ranges from 5mm to 25mm based on application needs. Manufacturers can tailor dimensions to fit specific machinery or protective setups. Custom designs may require longer lead times.

(Wear Resistant Boron Carbide Ceramic Tile B4C Ceramic Industrial Plate)

REQUEST A QUOTE

RELATED PRODUCTS

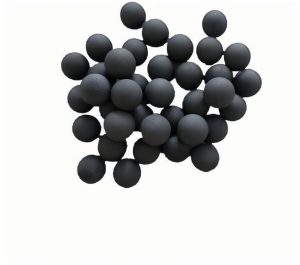

High Purity B4C Boron Carbide Ceramic Grinding Balls

R Silicon Carbide High Hardness Boron Carbide Plate Silicon Carbide Sheet B4C SIC Ceramic Block

Whole Customized Alumina Boron Carbide PE Weighted Ceramic Vest Plate Protection Plates III

High Quality China Factory Supply Boron Carbide Ceramic Plate B4C

China Factory Supply B4C Ceramic Sheet Boron Carbide Monolithic Plate Protection Customizable Welding Cutting Punching Square