Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

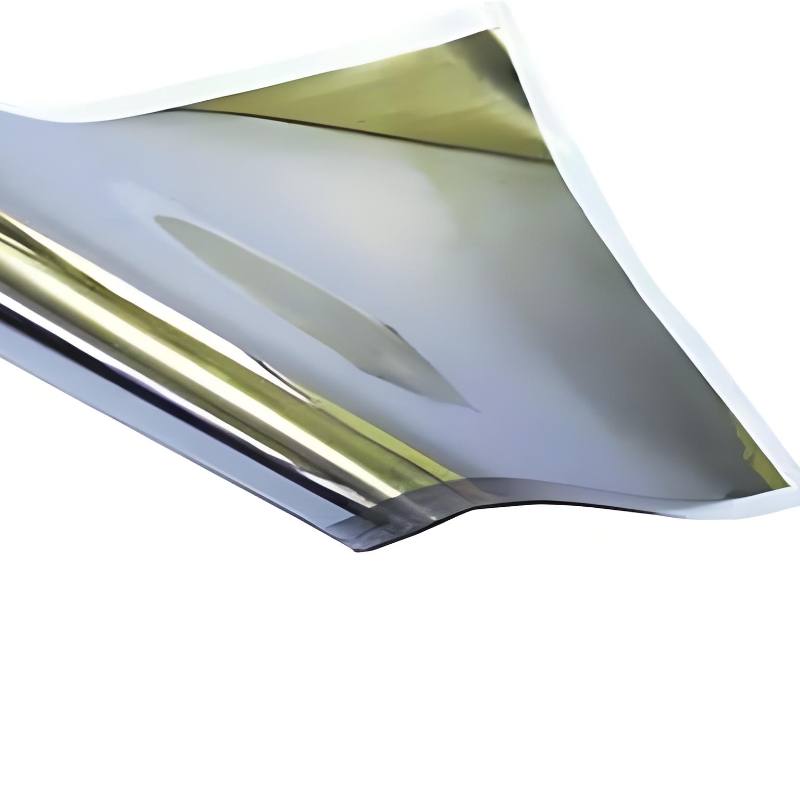

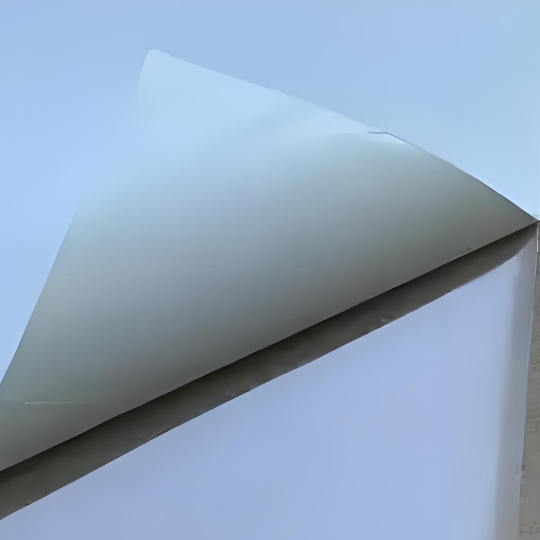

Overview of Boron Nitride Film:

Boron Nitride (BN) films are thin layers of a compound composed of boron and nitrogen atoms. These films have garnered significant attention due to their unique properties, which make them suitable for a wide range of applications in electronics, optics, and thermal management.

Features of Boron Nitride Film:

- High Thermal Conductivity: Boron nitride films have high thermal conductivity, making them excellent for dissipating heat in electronic devices.

- Electrical Insulation: Despite their thermal conductivity, the films are also electrical insulators, which is critical for semiconductor device manufacturing.

- Chemical Stability: BN films show resistance to chemical reactions at high temperatures, which adds to their durability in harsh environments.

- Mechanical Strength: They possess good mechanical strength and hardness, especially in the form of cubic boron nitride (c-BN), which is second only to diamond in hardness.

- Optical Transparency: Hexagonal boron nitride (h-BN), in particular, has optical transparency in the ultraviolet to infrared range, which is beneficial for optical applications.

- Low Dielectric Constant: This property is important for reducing parasitic capacitance in high-frequency devices.

Specifications of Boron Nitride Film:

| Property | Specification/Value | Notes |

| Thermal Conductivity | Up to ~200 W/m·K (in-plane for h-BN) | Highly dependent on crystal orientation and purity. |

| Electrical Resistivity | > 10^13 Ω·cm | Excellent electrical insulation property. |

| Dielectric Constant | ~4-6 (for h-BN) | Low dielectric constant reduces parasitic capacitance. |

| Coefficient of Thermal Expansion (CTE) | ~2.5 × 10^-6/K (for h-BN) | Similar CTE to silicon, beneficial for semiconductor applications. |

| Hardness | Vickers hardness up to ~45 GPa (for c-BN) | High hardness, especially cubic BN, second only to diamond. |

| Melting Point | ~3000°C | High melting point contributes to thermal stability. |

| Chemical Stability | Stable in many acids and bases at high temperatures | Exceptional resistance to chemical attack. |

| Optical Transparency | Transparent from UV to IR | Particularly useful for optical applications. |

| Friction Coefficient | As low as ~0.16 (for h-BN) | Makes it suitable for lubrication in vacuum or inert environments. |

| Band Gap | ~5.9 eV (for h-BN) | Wide bandgap material suitable for high-power and high-frequency devices. |

| Deposition Methods | CVD, PVD, ALD, Sol-Gel | Various methods available for different applications. |

| Film Thickness | Can be deposited from nanometers to micrometers | Thickness depends on application requirements and deposition technique. |

Applications of Boron Nitride Film:

1. Thermal Management

Heat Sinks and Thermal Interface Materials: BN films can efficiently dissipate heat from electronic components, improving performance and longevity.

High-Power Electronics: Used in devices like power transistors and modules where efficient heat dissipation is critical.

2. Semiconductor Devices

Insulating Layers: Act as protective coatings or barriers in semiconductor fabrication to prevent unwanted electrical conduction.

Gate Dielectrics: Due to its low dielectric constant, BN can be used in the gate stacks of MOSFETs to reduce parasitic capacitance and improve switching speeds.

3. Optoelectronics

Light Emitting Diodes (LEDs): BN films can be used as a substrate or buffer layer for gallium nitride-based light emitting diodes to improve efficiency and reduce defect density.

Photodetectors and solar cells: BN films offer good optical transparency and resistance to harsh environments.

4. Catalysis

Catalyst Supports: BN films provide a stable platform for catalyst particles in various chemical reactions, particularly in high-temperature processes.

Electrocatalysis: Used in electrochemical cells for energy conversion and storage systems.

5. Surface Coatings

Wear Resistance: Applied to surfaces to enhance wear resistance and durability.

Friction Reduction: Utilized as solid lubricants in vacuum or inert environments where conventional lubricants cannot be used.

6. Flexible Electronics

Flexible Substrates: BN films can be integrated into flexible electronics due to their mechanical flexibility and thermal management capabilities.

Wearable Devices: Used in wearable technology where thin, flexible, and durable materials are required.

7. Nanotechnology

Nanodevices: BN nanotubes and nanosheets are explored for their unique quantum properties in nanoelectronic and optoelectronic devices.

Sensors: High sensitivity and stability make BN films suitable for various types of sensors, including gas sensors and biosensors.

8. Space Applications

Radiation Shielding: BN’s atomic structure provides effective shielding against radiation, making it useful in spacecraft components.

Extreme Environment Components: Its stability under extreme conditions makes it ideal for space exploration equipment.

9. Biomedical Applications

Bio-compatible Coatings: BN films can be used for biocompatible coatings on medical implants or devices due to their non-reactive nature.

Drug Delivery Systems: Nanoparticles of BN can be functionalized for targeted drug delivery.

10. Energy Storage

Battery Electrodes: BN-coated electrodes can improve the performance and safety of lithium-ion batteries by providing a stable interface between the electrolyte and electrode materials.

Company Profile

Advanced Ceramics founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2012, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Aluminum Nitride Ceramic Products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

FAQs of Boron Nitride Film

1.What is a boron nitride Film?

A: A boron nitride (BN) film is a thin layer of material composed of boron and nitrogen atoms. This compound can exist in various crystal structures, the most common being hexagonal boron nitride (h-BN), which resembles the structure of graphite, and cubic boron nitride (c-BN), which has a structure similar to diamond. BN films are deposited on substrates using different methods such as chemical vapor deposition (CVD), physical vapor deposition (PVD), atomic layer deposition (ALD), or sol-gel processes.

2. What are the benefits of boron nitride Film?

A: Boron nitride (BN) films offer a multitude of benefits that make them highly desirable in various industries and applications. Here are the key advantages: High Thermal Conductivity, Excellent Electrical Insulation, Chemical Stability, Low Friction Coefficient, Environmental Stability.

3. What industries use boron nitride Film?

A: Boron nitride (BN) films find applications across a wide array of industries due to their exceptional properties. Such as electronics and semiconductors, optoelectronics, automotive, biomedical, manufacturing and machining, chemical processing.

4. Can boron nitride Films be used in high-temperature environments?

A: Yes, boron nitride (BN) films are particularly well-suited for use in high-temperature environments. BN films can withstand very high temperatures, with a melting point around 3000℃ for hexagonal boron nitride (h-BN). This makes them stable and functional even at elevated temperatures where many other materials would degrade or fail.

5. Are boron nitride Films environmentally friendly?

A: Boron nitride (BN) films can be considered environmentally friendly in several aspects, but it’s important to evaluate their environmental impact across the entire lifecycle, including production, use, and disposal.

REQUEST A QUOTE

RELATED PRODUCTS

High Purity BN Insulating Ceramic Plate Boron Nitride Sheet

Hexagonal Boron Nitride Tube Boron Nitride Ceramic Parts

Boron Nitride Ceramic Insulating Tube

BN Ceramic Plate High Purity 99 Boron Nitride Ceramic Sheetboron Nitride Substrate Customized

Hexagonal BN Boron Nitride Ring Insulating Ceramic Part