Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Boron Nitride Ceramic

Boron Nitride (BN) ceramic is a unique material renowned for its exceptional properties, making it highly valuable in various industrial applications. It exists in multiple forms, primarily hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride (w-BN). Hexagonal BN, the most common form, is often compared to graphite due to its lubricious and thermally conductive yet electrically insulating nature. Boron Nitride ceramics are synthesized under high temperatures and pressures, offering a rare combination of properties not found in many other materials.

Features of Boron Nitride Ceramic

Thermal Conductivity: Excellent thermal conductivity, especially in the hexagonal form, allowing efficient heat dissipation.

Electrical Insulation: Outstanding electrical insulation properties make it ideal for electrical applications requiring thermal management.

Chemical Stability: Highly resistant to chemical attacks, including strong acids and bases, ensuring durability in harsh environments.

Thermal Shock Resistance: Superior resistance to thermal shock, enabling it to withstand rapid temperature changes without cracking.

Mechanical Strength: Good mechanical strength at both room and elevated temperatures, although this can vary with the form of BN.

Lubricity: Self-lubricating property due to its layered structure, which reduces friction and wear in moving parts.

Non-Toxic: Safe to use in various settings, including medical and food processing industries, due to its non-toxic nature.

High-Temperature Performance: Maintains stability at extremely high temperatures, exceeding 1000°C in inert atmospheres, making it suitable for refractory applications.

(Custom Made Insulating High Temperature Corrosion Resistant BN Ceramic Parts Boron Nitride Ceramic Block)

Specification of Custom Made Insulating High Temperature Corrosion Resistant BN Ceramic Parts Boron Nitride Ceramic Block

Custom Made Insulating High Temperature Corrosion Immune BN Ceramic Parts are crafted for demanding industrial applications. These boron nitride ceramic blocks use exceptional thermal security, chemical resistance, and electrical insulation. The product endures extreme temperatures up to 2000 ° C in inert ambiences. In oxidizing settings, it performs reliably at 800 ° C. This makes it ideal for high-temperature heating systems, liquified steel handling, and semiconductor processing.

The ceramic components feature low thermal expansion, decreasing cracking under rapid temperature changes. High thermal conductivity guarantees efficient warmth dissipation. Unlike metals, boron nitride continues to be electrically protecting also at elevated temperature levels. This mix is crucial for applications calling for both thermal administration and electrical safety and security.

Rust resistance is a vital advantage. BN ceramic resists strike from acids, antacid, and molten metals like aluminum and copper. It remains secure in reactive environments usual in chemical handling or metallurgy. The non-wetting surface area stops bond of liquified products, minimizing upkeep requirements.

Modification options consist of precise dimensions, shapes, and surface area coatings. Components are machined into blocks, plates, tubes, or complicated geometries. Limited tolerances down to ± 0.1 mm are achievable. The product’s machinability enables complex designs without jeopardizing structural stability. Thickness arrays from 1.6 to 2.2 g/cm THREE, tailored for details thermal or mechanical requirements.

BN ceramic blocks show high dielectric strength, perfect for electric insulation in high-voltage tools. Low friction buildings make them ideal for high-wear applications. The material is safe and chemically inert, fulfilling safety criteria for food handling or medical devices.

Manufacturing utilizes hot-pressed boron nitride powder, guaranteeing uniform thickness and marginal porosity. Advanced sintering strategies enhance mechanical toughness. Quality assurance includes screening for thermal conductivity, hardness, and chemical pureness. Customized orders include certifications for product structure and efficiency metrics.

Applications extend aerospace, electronic devices, energy, and industrial manufacturing. Typical usages include crucibles, thermocouple defense tubes, and diffusion heater elements. The product’s flexibility addresses challenges in atmospheres where steels or polymers stop working.

Personalized requirements fit one-of-a-kind operational requirements. Technical assistance is available for product selection and layout optimization. Lead times vary based upon complexity, with rapid prototyping options for urgent requirements. Mass orders receive competitive pricing while maintaining strict top quality criteria.

(Custom Made Insulating High Temperature Corrosion Resistant BN Ceramic Parts Boron Nitride Ceramic Block)

Applications of Custom Made Insulating High Temperature Corrosion Resistant BN Ceramic Parts Boron Nitride Ceramic Block

Customized insulating high-temperature corrosion-resistant BN ceramic components offer essential duties across multiple industries. Boron nitride porcelains supply one-of-a-kind homes. They combine high thermal stability with superb chemical resistance. These products hold up against extreme temperature levels up to 2000 ° C in inert atmospheres. They preserve structural stability under quick thermal cycling. This makes them ideal for demanding commercial settings.

In metallurgy, BN ceramic blocks function as crucibles for melting alloys. They stop contamination during high-purity metal handling. Their non-reactive surface area makes sure clean puts. The low thermal expansion coefficient reduces cracking threats. Furnace components like thermocouple sheaths utilize BN ceramics. They provide trusted insulation in continual high-heat procedures.

Aerospace applications benefit from BN’s light-weight nature. Rocket nozzle linings make use of these porcelains. They endure extreme exhaust temperatures without erosion. Electric insulation properties suit plasma arc tools. BN parts isolate electrodes while resisting arc erosion. Semiconductor producing depends on boron nitride for wafer handling fixtures. The material’s electrical insulation prevents current leakage. It guarantees accurate temperature control during deposition processes.

Chemical handling plants utilize BN porcelains for reactor linings. They stand up to destructive acids and liquified salts. Pump parts made from BN deal with aggressive media. The non-wetting surface protects against material accumulation. Glass production utilizes BN parts for molds. They release liquified glass smoothly. This lowers issues in high-precision optical parts.

BN ceramic blocks device easily right into complicated shapes. Suppliers tailor dimensions for details devices demands. Custom-made styles include threaded inserts, nozzles, and custom-made accounts. The material’s machinability allows limited resistances. Post-processing choices consist of brightening or finish. These enhance performance in specialized applications.

High-temperature electric systems incorporate BN insulators. They separate conductors in vacuum cleaner atmospheres. Their dielectric stamina stops short circuits. BN’s thermal conductivity help warmth dissipation. This twin functionality supports compact part layouts. Automotive screening uses BN components for sensing unit insulation. They guarantee accurate readings in engine performance trials.

Boron nitride porcelains adapt to special operational challenges. Industries worth their mix of thermal and chemical durability. Customized configurations resolve details technical demands. This convenience drives fostering across advanced manufacturing industries.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Custom Made Insulating High Temperature Corrosion Resistant BN Ceramic Parts Boron Nitride Ceramic Block

What is BN ceramic?

BN ceramic stands for boron nitride ceramic. It is a synthetic material known for high temperature resistance and corrosion resistance. It works well in extreme environments. The material has good thermal conductivity but stays electrically insulating. These properties make it suitable for industrial applications needing heat management and chemical stability.

Why choose BN ceramic over other ceramics?

BN ceramic handles higher temperatures than materials like alumina or silicon nitride. It resists thermal shock better. The material does not react with most acids, alkalis, or molten metals. It can be machined into precise shapes before sintering. This flexibility reduces post-processing costs.

What temperature can BN ceramic parts withstand?

BN ceramic parts operate continuously up to 1800°C in inert atmospheres. In air, they withstand temperatures up to 900°C without degrading. This makes them ideal for furnaces, semiconductor manufacturing, and metallurgy. The material maintains structural integrity under rapid temperature changes.

Can BN ceramic parts be customized?

Yes. BN ceramic parts are tailored to specific shapes, sizes, and performance needs. Customization includes machining pre-sintered blocks into complex geometries. Tolerances as tight as ±0.1 mm are achievable. Surface finishes and coatings can be added for enhanced corrosion resistance or reduced friction.

How does BN ceramic resist corrosion?

BN ceramic is chemically inert. It does not react with acids, molten glass, or metal slags. This prevents erosion or contamination in harsh chemical environments. The material’s dense structure blocks penetration by corrosive substances. It performs reliably in applications like molten metal handling or chemical reactor linings.

(Custom Made Insulating High Temperature Corrosion Resistant BN Ceramic Parts Boron Nitride Ceramic Block)

REQUEST A QUOTE

RELATED PRODUCTS

High Purity Easily Machinable Boron Nitride HPBN BN Ceramic Rod

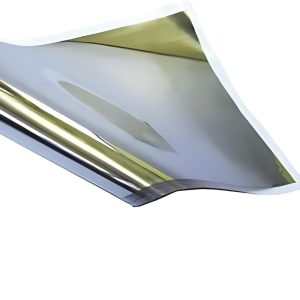

Chemically Stable Boron Nitride Ceramic BN Film

Corrosion Resistant Aluminum Nitride Composite Boron Nitride Ceramic Part AIN Ceramic Plate

99.8% 100-200nm Hexagonal Boron Nitride Powder Nano Boron Nitride Powder Ceramic Raw Materials Additive Lubricant

99% Hexagon Hbn Boron Nitride Bn Ceramic Tube Rod Pipe