Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Boron Nitride Ceramic

Boron Nitride (BN) ceramic is a unique material renowned for its exceptional properties, making it highly valuable in various industrial applications. It exists in multiple forms, primarily hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride (w-BN). Hexagonal BN, the most common form, is often compared to graphite due to its lubricious and thermally conductive yet electrically insulating nature. Boron Nitride ceramics are synthesized under high temperatures and pressures, offering a rare combination of properties not found in many other materials.

Features of Boron Nitride Ceramic

Thermal Conductivity: Excellent thermal conductivity, especially in the hexagonal form, allowing efficient heat dissipation.

Electrical Insulation: Outstanding electrical insulation properties make it ideal for electrical applications requiring thermal management.

Chemical Stability: Highly resistant to chemical attacks, including strong acids and bases, ensuring durability in harsh environments.

Thermal Shock Resistance: Superior resistance to thermal shock, enabling it to withstand rapid temperature changes without cracking.

Mechanical Strength: Good mechanical strength at both room and elevated temperatures, although this can vary with the form of BN.

Lubricity: Self-lubricating property due to its layered structure, which reduces friction and wear in moving parts.

Non-Toxic: Safe to use in various settings, including medical and food processing industries, due to its non-toxic nature.

High-Temperature Performance: Maintains stability at extremely high temperatures, exceeding 1000°C in inert atmospheres, making it suitable for refractory applications.

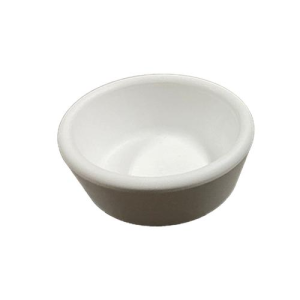

(Customized Hot Pressed Hexagonal BN Boron Nitride Ceramic Structural Parts)

Specification of Customized Hot Pressed Hexagonal BN Boron Nitride Ceramic Structural Parts

Personalized Hot Pushed Hexagonal BN Boron Nitride Ceramic Structural Parts are engineered for high-performance applications needing thermal stability, electrical insulation, and chemical resistance. These parts utilize hexagonal boron nitride (h-BN), a ceramic product recognized for low friction, high thermal conductivity, and resistance to severe temperature levels. The hot-pressing method guarantees thick, uniform frameworks with enhanced mechanical stamina.

The material withstands temperatures approximately 2000 ° C in inert ambiences. It remains secure in oxidizing atmospheres approximately 900 ° C. The thermal conductivity arrays between 15-30 W/m · K, outperforming lots of porcelains. Its low thermal growth decreases fracturing under fast temperature level shifts. The dielectric toughness exceeds 35 kV/mm, making it ideal for electric insulation.

Modification alternatives cover forms, dimensions, and densities. Common kinds consist of plates, tubes, crucibles, and nozzles. Dimensions are tailored to customer demands. Precision machining guarantees limited tolerances for complex geometries. Surface surfaces can be readjusted for details applications.

These parts resist molten steels, salts, and acids. They are non-reactive with many chemicals. This makes them suitable for extreme commercial atmospheres. Applications extend semiconductor processing, metallurgy, aerospace, and high-temperature heating systems. They work as crucibles for metal melting, insulators in digital tools, and components in plasma arc systems.

The hot-pressing procedure involves condensing h-BN powder under high stress and temperature. This eliminates porosity, improving toughness. The end product has a purity degree over 99%, making certain minimal pollutants. Density arrays from 1.8 to 2.1 g/cm TWO, balancing toughness and lightweight buildings.

Quality assurance consists of rigorous screening for thermal, mechanical, and electric performance. Each set satisfies market criteria for consistency. Custom-made orders call for comprehensive specifications to make certain compatibility with operating problems.

The product’s lubricity lowers wear in relocating components. It operates properly in vacuum settings without outgassing. Long life span decreases substitute expenses. Maintenance needs are very little due to inherent corrosion resistance.

Custom-made Hot Pushed Hexagonal BN Boron Nitride Ceramic Structural Parts offer reliability in demanding setups. Their flexibility across industries stems from tailored styles and robust material homes. Performance under anxiety ensures they fulfill crucial functional requirements.

(Customized Hot Pressed Hexagonal BN Boron Nitride Ceramic Structural Parts)

Applications of Customized Hot Pressed Hexagonal BN Boron Nitride Ceramic Structural Parts

Personalized hot-pressed hexagonal BN boron nitride ceramic structural components serve critical roles across numerous industries. Their unique buildings make them excellent for demanding environments. High thermal security enables them to stand up to severe temperatures without weakening. Excellent electrical insulation makes sure safety in digital applications. Chemical inertness protects against reactions with destructive substances. These functions expand their functionality in specialized industries.

The semiconductor market counts greatly on these components. They work as crucibles for melting and handling high-purity metals. Their non-reactive nature prevents contamination throughout crystal development processes. Shielding elements in semiconductor production devices benefit from their resistance to thermal shock. This makes sure consistent efficiency in quick home heating or cooling cycles.

Metallurgical applications utilize BN ceramic components for high-temperature heating system parts. They work as linings and shields in atmospheres surpassing 2000 ° C. Molten steel taking care of systems integrate them due to their non-wetting residential or commercial properties. This lowers material attachment and prolongs equipment life expectancy. Continual casting mold and mildews take advantage of their thermal conductivity to handle solidification prices efficiently.

Glass manufacturing uses these ceramics in developing tools and rollers. Their low thermal development lessens distortion during glass shaping. High-temperature sensors and thermocouple security tubes use BN porcelains for precise measurements. This improves procedure control in glass assembly line.

Aerospace and vehicle industries apply BN ceramic components in thermal management systems. They shield elements in engines and exhaust systems. High-voltage equipment utilizes them as insulators to avoid electrical leakage. Their lightweight nature sustains gas performance objectives without compromising durability.

Electronic devices gain from BN porcelains in heat sinks and circuit substrates. Their thermal conductivity dissipates heat from high-power gadgets. Laser modern technology incorporates them as windows and mirrors as a result of optical openness in infrared ranges. This ensures reliable efficiency in cutting and welding systems.

Custom-made shapes and sizes satisfy details operational needs. Precision machining dressmakers parts for complicated geometries. Industries gain optimized services for special challenges. The mix of mechanical strength and thermal resistance makes BN porcelains crucial in sophisticated design applications.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Customized Hot Pressed Hexagonal BN Boron Nitride Ceramic Structural Parts

What is hot pressed hexagonal boron nitride ceramic?

Hot pressed hexagonal boron nitride (BN) ceramic is a synthetic material made under high heat and pressure. It has a layered structure similar to graphite. This process creates parts with high thermal stability, low friction, and excellent electrical insulation. It works well in extreme temperatures and corrosive environments.

Why pick hexagonal BN over other ceramics?

Hexagonal BN stands out for its thermal shock resistance. It handles sudden temperature changes without cracking. It stays stable in air up to 900°C and in inert gases up to 2,000°C. It resists most molten metals and chemicals. Other ceramics like alumina or silicon carbide lack these combined properties.

Can these parts be customized for specific needs?

Yes. Manufacturers shape hexagonal BN into rods, plates, tubes, or complex geometries using machining processes like grinding or drilling. Custom sizes, thicknesses, and surface finishes are possible. This flexibility suits applications in semiconductor processing, metallurgy, and aerospace.

What temperature limits do these parts have?

In oxygen-free environments, hexagonal BN withstands temperatures up to 2,000°C. In air, it remains stable up to 900°C. It outperforms many metals and polymers in high-heat settings. Its low thermal expansion reduces stress under rapid heating or cooling.

Where are these ceramic parts commonly used?

They serve in high-temperature furnaces as crucibles or insulators. Semiconductor industries use them for wafer handling and diffusion barriers. Metal casting relies on them for molds and release agents. Aerospace applications include radar windows and microwave components. Their electrical insulation and thermal conductivity make them ideal for electronics cooling systems.

(Customized Hot Pressed Hexagonal BN Boron Nitride Ceramic Structural Parts)

REQUEST A QUOTE

RELATED PRODUCTS

High Purity BN Insulating Ceramic Plate Boron Nitride Sheet

Hot Pressed BN Ceramic Insulation Tube Boron Nitride Seal Ring Solid Roller Cylinder Ring

High temperature high purity 99% BN boron nitride crucible

High Purity BN Ceramic Boron Nitride Crucible for Melting

” Ceramics” Hot Pressed Boron Nitride BN Ceramic Nozzle Tube