Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Boron Nitride Ceramic

Boron Nitride (BN) ceramic is a unique material renowned for its exceptional properties, making it highly valuable in various industrial applications. It exists in multiple forms, primarily hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride (w-BN). Hexagonal BN, the most common form, is often compared to graphite due to its lubricious and thermally conductive yet electrically insulating nature. Boron Nitride ceramics are synthesized under high temperatures and pressures, offering a rare combination of properties not found in many other materials.

Features of Boron Nitride Ceramic

Thermal Conductivity: Excellent thermal conductivity, especially in the hexagonal form, allowing efficient heat dissipation.

Electrical Insulation: Outstanding electrical insulation properties make it ideal for electrical applications requiring thermal management.

Chemical Stability: Highly resistant to chemical attacks, including strong acids and bases, ensuring durability in harsh environments.

Thermal Shock Resistance: Superior resistance to thermal shock, enabling it to withstand rapid temperature changes without cracking.

Mechanical Strength: Good mechanical strength at both room and elevated temperatures, although this can vary with the form of BN.

Lubricity: Self-lubricating property due to its layered structure, which reduces friction and wear in moving parts.

Non-Toxic: Safe to use in various settings, including medical and food processing industries, due to its non-toxic nature.

High-Temperature Performance: Maintains stability at extremely high temperatures, exceeding 1000°C in inert atmospheres, making it suitable for refractory applications.

(Factory Cubic Boron Nitride Blade CBN Solid Ceramic Blade Hard Outer Ring CNC Roll Brake Drum Milling Blade Carbide Insert)

Specification of Factory Cubic Boron Nitride Blade CBN Solid Ceramic Blade Hard Outer Ring CNC Roll Brake Drum Milling Blade Carbide Insert

The Manufacturing Facility Cubic Boron Nitride Blade (CBN Strong Ceramic Blade) is designed for high-precision machining applications. It features a difficult external ring made from cubic boron nitride, a material known for outstanding hardness and heat resistance. This blade is excellent for reducing difficult materials like solidified steel, cast iron, and alloys. Its strong ceramic framework guarantees stability throughout heavy-duty procedures, decreasing wear with time.

The blade is compatible with CNC machines, roll brakes, drum mills, and similar tools. It keeps intensity also under high temperatures, reducing downtime for substitutes. The carbide insert at the core improves sturdiness, permitting repeated use without loss of performance.

Key requirements consist of a size range of 50– 300 mm and density choices from 2 mm to 10 mm. Customized sizes are offered to satisfy specific machining needs. The CBN layer is bonded to a steel body, incorporating toughness with adaptability. This style withstands cracking and cracking under stress and anxiety, expanding the blade’s lifespan.

Applications consist of precision milling of brake drums, blades, and gears. The blade produces smooth finishes, minimizing the demand for additional polishing. Its high-speed capacity fits industrial settings requiring performance.

Compared to standard carbide blades, this CBN blade provides to five times longer life span. It lowers product waste by maintaining constant reducing precision. The ceramic part prevents deterioration, making it appropriate for moist or unpleasant settings.

Setup is straightforward, with conventional placing systems for quick combination into existing configurations. Routine cleaning and cooling during use maximize efficiency. Very little maintenance is needed as a result of the blade’s resistance to deformation.

Quality control guarantees each blade meets strict resistance standards. Extensive screening checks for equilibrium, edge honesty, and warmth dissipation. The result is a reliable tool for producers aiming to enhance productivity and cut operational costs.

Security attributes include anti-vibration layout and enhanced edges to stop crashes throughout high-speed rotation. The blade is packaged safely to stay clear of damages during delivery. Mass orders are sustained for massive industrial clients.

This product is backed by a warranty covering production defects. Technical support is available to assist with selection and troubleshooting. The Manufacturing Facility CBN Blade is an affordable solution for accuracy machining obstacles.

(Factory Cubic Boron Nitride Blade CBN Solid Ceramic Blade Hard Outer Ring CNC Roll Brake Drum Milling Blade Carbide Insert)

Applications of Factory Cubic Boron Nitride Blade CBN Solid Ceramic Blade Hard Outer Ring CNC Roll Brake Drum Milling Blade Carbide Insert

The Factory Cubic Boron Nitride Blade (CBN) is a high-performance device developed for precision machining. It takes care of hard products like hardened steel, cast iron, and alloys. The blade’s strong ceramic structure ensures toughness. It resists wear also under high warmth. Industries like auto and aerospace depend on it for durable jobs. The CBN blade cuts efficiently. It minimizes product waste. This improves performance in assembly line.

The Hard Outer Ring CNC Roll is developed for shaping metal parts. It collaborates with CNC makers to create accurate components. The roll’s outer layer uses CBN innovation. This makes it solid versus abrasion. It mills intricate shapes without shedding intensity. Manufacturers use it for engine components, gears, and hydraulic parts. The result corresponds quality.

Brake Drum Milling Blades concentrate on vehicle repair and production. These blades device brake drums promptly. They maintain limited tolerances. The CBN side remains sharp longer than common tools. Auto mechanics conserve time on substitutes. Workshops decrease downtime. The blades work on actors iron and composite products.

Carbide Inserts enhance CBN blades in reducing applications. They are made from tungsten carbide. This ensures hardness and heat resistance. Inserts connect to milling and transforming tools. They equipment steels, plastics, and composites. The inserts handle high-speed procedures. They last longer than typical steel tools. Factories use them for automation.

CBN Solid Ceramic Blades excel in high-speed machining. They grind and reduce without breaking. The ceramic base absorbs resonances. This improves surface finish. Electronic devices manufacturers utilize them for accuracy elements. The blades reduce energy usage. They reduced functional expenses gradually.

These devices adjust to numerous industrial needs. They perform in severe problems. Individuals benefit from longer device life. Upkeep prices decrease. Production speeds increase. Each application highlights the blend of advanced materials and design. The emphasis remains on delivering integrity and accuracy across industries.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Factory Cubic Boron Nitride Blade CBN Solid Ceramic Blade Hard Outer Ring CNC Roll Brake Drum Milling Blade Carbide Insert

What is the Factory Cubic Boron Nitride Blade used for?

This blade cuts tough materials like hardened steel, cast iron, and alloys. It works best for CNC machining, brake drum milling, and shaping heavy-duty parts. The CBN material stays sharp under high heat, making it ideal for jobs needing precision over long periods.

Why pick a CBN blade over regular carbide tools?

CBN blades last longer. They handle higher temperatures without wearing down. Carbide tools lose edge faster in extreme conditions. The boron nitride structure resists abrasion better, reducing replacements. This saves time and costs in industrial settings.

What materials can this blade cut?

It cuts hard metals like brake drums, engine components, and tool steels. Avoid soft materials like aluminum or plastics. The blade’s hardness might chip edges on softer surfaces. Stick to ferrous metals for best results.

How do I maintain the blade’s performance?

Clean it after use to remove metal chips. Check for damage or dullness regularly. Use coolant during heavy machining to prevent overheating. Store it dry to avoid rust. Proper care keeps the blade efficient and extends its life.

Can this blade fit standard CNC machines?

Yes. It fits most CNC milling setups. Confirm the blade’s size and shank match your machine specs. The design focuses on compatibility with common CNC systems. Reach out to the supplier if unsure about measurements.

(Factory Cubic Boron Nitride Blade CBN Solid Ceramic Blade Hard Outer Ring CNC Roll Brake Drum Milling Blade Carbide Insert)

REQUEST A QUOTE

RELATED PRODUCTS

Boron Nitride Ceramic Rod With BN Shaft Industrial Ceramic Composite Stick For Processing Customizable Cutting

Boron Nitride Ceramic Tube Pipe Ceramic Protection Insulating Tube

Boron Nitride (R-BN) Used for Making Hot-pressed Ceramic Parts

Hexagonal Boron Nitride Powder Ceramic Material 20-50um CAS 10043-11-5 Industrial Pricing Available

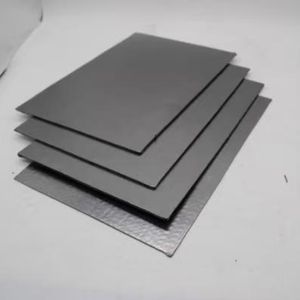

High Purity BN Insulating Ceramic Plate Boron Nitride Sheet