Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

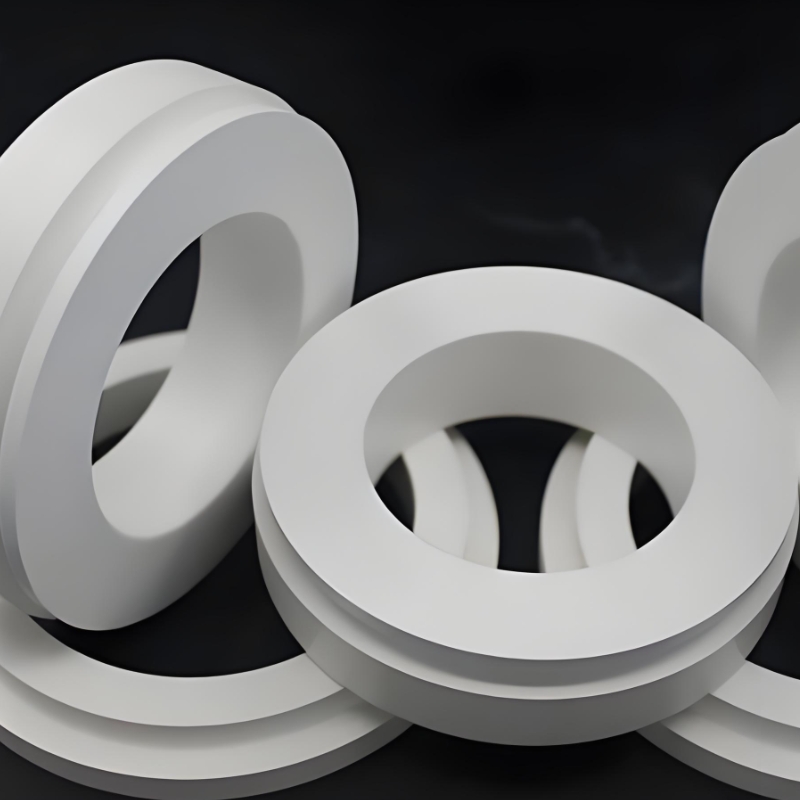

Overview of Boron Nitride Ring:

Boron nitride (BN) rings, much like BN tubes, leverage the exceptional properties of boron nitride to serve a variety of applications. These rings are typically manufactured from hexagonal boron nitride (h-BN), which is known for its layered structure similar to graphite, or cubic boron nitride (c-BN), noted for its hardness and thermal stability.

Features of Boron Nitride Ring:

1.High Thermal Conductivity:

Highly efficient thermal conduction makes BN rings suitable for thermal management applications.

2. Excellent Electrical Insulation:

Despite their high thermal conductivity, they are highly electrically insulating and therefore safe in environments where electrical isolation is required.

3. Chemical Stability:

BN rings are resistant to most chemicals even at high temperatures, ensuring durability in corrosive environments.

4. Mechanical Strength:

High hardness and wear resistance, especially in the c-BN form, contribute to the long term use of the parts.

5. Low Coefficient of Thermal Expansion (CTE):

The low coefficient of thermal expansion reduces the risk of cracking and deformation during temperature changes and maintains dimensional stability.

6. Lubricity:

The laminar structure of h-BN provides natural lubrication, which helps reduce friction in moving parts.

7. Optical Transparency:

Transparent over a wide range of wavelengths, suitable for optical devices.

8. Wide Bandgap:

Wide bandgap, suitable for high power and high frequency electronic equipment.

9. Non-toxic and Chemically Inert:

Environmentally friendly, safe to handle and dispose.

Specifications of Boron Nitride Ring:

| Property | Typical Value | Unit | Notes |

| Material Type | Hexagonal Boron Nitride (h-BN) | Layered structure similar to graphite; most common form for rings | |

| Cubic Boron Nitride (c-BN) | Exceptional hardness and thermal stability | ||

| Density | 2.27 | g/cm³ | For h-BN |

| 3.48 | g/cm³ | For c-BN | |

| Hardness (Vickers) | ~10 GPa | For h-BN | |

| ~45 GPa | For c-BN, comparable to diamond | ||

| Melting Point | >3,000 | °C | High melting point ensures stability in high-temperature environments |

| Thermal Conductivity | 60 – 300 | W/m·K | Along the basal plane for h-BN |

| 10 – 100 | W/m·K | Perpendicular to the basal plane | |

| Coefficient of Thermal Expansion (CTE) | 2.5 – 4.5 | ×10⁻⁶/°C | Low CTE minimizes thermal expansion and contraction |

| Electrical Resistivity | >10¹² | Ω·cm | Excellent electrical insulation |

| Dielectric Strength | 10 – 20 | kV/mm | Good dielectric properties |

| Chemical Stability | Chemically inert | Resistant to most chemicals, even at high temperatures | |

| Friction Coefficient | 0.1 – 0.2 | Self-lubricating properties | |

| Porosity | <1% | Typically very low porosity for dense sintered products | |

| Flexural Strength | 200 – 400 | MPa | Depends on manufacturing process and material type |

| Compressive Strength | 1,000 – 3,000 | MPa | High compressive strength suitable for mechanical applications |

| Transparency | Transparent to UV to IR | Useful for optical applications | |

| Bandgap Energy | 5.9 – 6.2 | eV | Wide bandgap makes it suitable for high-power electronic devices |

| Neutron Absorption Cross Section | Moderate | barns | Beneficial for nuclear applications |

Applications of Boron Nitride Ring:

1.Thermal Management

Heat Exchangers and Cooling Sleeves: BN rings effectively manage heat in electronic devices and machinery, providing long-lasting, effective solutions for thermal management.

Thermal Interface: Used as a thermal interface material between a heat source and a heat sink, it improves heat transfer efficiency.

2. Electronics and Semiconductors

Substrates and Insulation: Ideal for substrates and insulation in semiconductor devices to provide thermal management and electrical isolation.

Heat Sinks: Critical for managing heat in power electronics, CPUs, GPUs and other high-performance electronic components to ensure optimal performance and longevity.

3. Automotive and Aerospace

Engine Components: Used in engine components that need to withstand high temperature and corrosive environment, contributing to durability and reliability.

Exhaust systems: For exhaust system components due to their thermal stability and chemical inertness, reducing wear and extending component life.

Power electronics: Critical for electric and hybrid vehicles, which requires effective thermal management of power modules and inverters.

Radiation shielding: Provides radiation protection for avionics and spacecraft to ensure reliable operation in the space environment.

4. Manufacturing and Processing

High-temperature molds: For molds used in metal casting and other manufacturing processes that require high thermal stability and low coefficient of thermal expansion (CTE).

Precision parts: for precision engineering applications where dimensional stability and thermal performance are critical.

Cutting Tool Coatings: Improve cutting tool durability, reduce wear and tear during machining, extend tool life and improve efficiency.

5. Chemical Processing

Reactor linings: Used in reactors where materials must withstand both aggressive chemicals and high temperatures to ensure long-term durability and safety.

Heat exchangers: Used in industrial processes involving high temperature heat transfer to maintain efficient thermal performance.

6. Metallurgy

Crucibles and refractory components: With their high melting point and chemical inertness, BN rings are used in crucibles and other refractory components in metal melting and alloying processes to ensure purity and consistency in metallurgical operations.

7. Energy production

Fuel cells: Used as a gas diffusion layer and catalyst carrier, BN’s high temperature properties and chemical stability are utilized to improve the efficiency and durability of fuel cells.

8. Biomedical Applications

Medical implants: Due to its non-reactivity and stability, it can be used as a biocompatible coating for implants or devices to ensure patient safety and device longevity.

Drug delivery systems: BN nanoparticles can be functionalized for targeted drug delivery by taking advantage of BN’s biocompatibility and stability in biological tissues.

9. Research and Development

Advanced Materials Development: Research and development of new materials with application-specific properties to advance materials science and engineering.

Nanotechnology: Explore the unique quantum properties of nanoelectronic and optoelectronic devices to advance technology and innovation.

10. Optics and Photonics

Lenses and Windows: The optical transparency of BN rings makes them suitable for use in lenses, windows and filters in optical devices, ensuring clear and stable performance under all conditions.

Photodetectors and Solar Cells: Benefit from their optical transparency and stability under harsh conditions, contributing to advanced photonic applications.

11. Environmental Applications

Catalyst carriers: Provide a stable platform for catalyst particles in a variety of chemical reactions, especially high temperature processes, promoting sustainable and efficient catalysis.

Electrocatalysis: Energy conversion and storage systems for electrochemical cells to support environmentally friendly technologies.

Company Profile

Advanced Ceramics founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2012, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Aluminum Nitride Ceramic Products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

FAQs of Boron Nitride Ring

1.What is a boron nitride ring?

A: A boron nitride ring is a mechanical component made from boron nitride (BN), typically in the form of hexagonal BN (h-BN) or cubic BN (c-BN). These rings are used in various applications due to their exceptional thermal conductivity, electrical insulation, chemical stability, and mechanical strength.

2. How are boron nitride rings manufactured?

A: BN rings can be produced using methods such as hot isostatic pressing (HIP), sintering, chemical vapor deposition (CVD), pressureless sintering, and extrusion. Each method has its advantages depending on the desired properties and shape complexity

3. Can boron nitride rings withstand high temperatures?

A: Yes, boron nitride rings can withstand very high temperatures. They have a melting point above 3,000℃ and remain stable at temperatures up to 1,000℃ in air and higher in vacuum or inert atmospheres.

4. Can boron nitride rings be customized?

A: Yes, many manufacturers offer custom sizes and shapes based on specific application needs. Customization can include dimensions, tolerances, surface finishes, and even material composition.

5. Are boron nitride rings safe to handle?

A: Yes, boron nitride is non-toxic and chemically inert, making it safe to handle. However, standard safety practices should be followed when working with any industrial material, including wearing appropriate personal protective equipment (PPE).

REQUEST A QUOTE

RELATED PRODUCTS

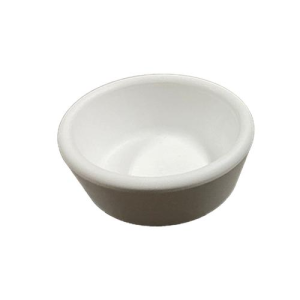

High Purity BN Ceramic Boron Nitride Crucible for Melting

Hot Pressed BN Ceramic Insulation Tube Boron Nitride Seal Ring Solid Roller Cylinder Ring

” Ceramics” Hot Pressed Boron Nitride BN Ceramic Nozzle Tube

High temperature high purity 99% BN boron nitride crucible

High Working Temperature Corrosion Resistance Boron Nitride Gasket