Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Boron Nitride Ceramic

Boron Nitride (BN) ceramic is a unique material renowned for its exceptional properties, making it highly valuable in various industrial applications. It exists in multiple forms, primarily hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride (w-BN). Hexagonal BN, the most common form, is often compared to graphite due to its lubricious and thermally conductive yet electrically insulating nature. Boron Nitride ceramics are synthesized under high temperatures and pressures, offering a rare combination of properties not found in many other materials.

Features of Boron Nitride Ceramic

Thermal Conductivity: Excellent thermal conductivity, especially in the hexagonal form, allowing efficient heat dissipation.

Electrical Insulation: Outstanding electrical insulation properties make it ideal for electrical applications requiring thermal management.

Chemical Stability: Highly resistant to chemical attacks, including strong acids and bases, ensuring durability in harsh environments.

Thermal Shock Resistance: Superior resistance to thermal shock, enabling it to withstand rapid temperature changes without cracking.

Mechanical Strength: Good mechanical strength at both room and elevated temperatures, although this can vary with the form of BN.

Lubricity: Self-lubricating property due to its layered structure, which reduces friction and wear in moving parts.

Non-Toxic: Safe to use in various settings, including medical and food processing industries, due to its non-toxic nature.

High-Temperature Performance: Maintains stability at extremely high temperatures, exceeding 1000°C in inert atmospheres, making it suitable for refractory applications.

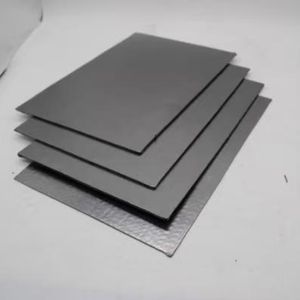

(High Precision Insulation Boron Nitride Composite Ceramic Bnsz)

Specification of High Precision Insulation Boron Nitride Composite Ceramic Bnsz

High Precision Insulation Boron Nitride Compound Ceramic Bnsz is created for requiring industrial applications calling for superior thermal management and electrical insulation. This material incorporates boron nitride with advanced ceramic matrices to accomplish high efficiency in extreme settings. The composite framework makes certain exceptional thermal security, preserving honesty at temperature levels up to 2000 ° C in inert atmospheres. Thermal conductivity is optimized for reliable warmth dissipation while preventing energy loss, making it ideal for high-temperature tools.

The product supplies remarkable electrical insulation, with a dielectric strength surpassing 20 kV/mm. This protects against present leak in high-voltage systems. Mechanical toughness is enhanced via precise ceramic bonding, providing a firmness ranking of 8.5 Mohs and compressive stamina over 500 MPa. These residential properties ensure resilience under heavy lots and abrasive problems.

Machinability is a crucial benefit. Unlike typical porcelains, Bnsz can be precision-machined right into complicated shapes without fracturing. This allows personalization for elements like heat sinks, nozzles, or shielding substratums. Surface area surfaces are smooth, minimizing rubbing and wear in dynamic applications.

Chemical resistance is an additional essential attribute. Bnsz withstands corrosion from acids, antacid, and molten steels. This makes it suitable for use in severe chemical handling or steel spreading atmospheres. The product does not react with most substances, guaranteeing lasting integrity.

Applications span multiple industries. In semiconductor manufacturing, Bnsz is made use of for wafer handling elements because of its low thermal development and contamination-free homes. Aerospace systems benefit from its lightweight yet robust framework. Energy sectors use it in crucibles for molten metal control or as insulators in high-voltage activators.

Ecological stability guarantees regular performance. Bnsz keeps properties throughout broad temperature fluctuations and prolonged exposure to UV or dampness. No additional coatings are required for outdoor or high-humidity installments.

Customizable qualities are readily available to fulfill particular demands. Alternatives include variations in thickness, thermal conductivity, or dielectric residential properties. Each batch undergoes strenuous high quality checks to make sure conformity with global requirements like ASTM or ISO.

The product is compatible with basic industrial bonding techniques. Combination into existing systems is uncomplicated, minimizing downtime throughout upgrades. Lead times for customized orders are competitive, with international delivery alternatives.

(High Precision Insulation Boron Nitride Composite Ceramic Bnsz)

Applications of High Precision Insulation Boron Nitride Composite Ceramic Bnsz

High Precision Insulation Boron Nitride Composite Ceramic Bnsz is a specialized material. It is developed for demanding commercial usages. It integrates high thermal conductivity with solid electrical insulation. These features make it ideal for innovative modern technology sectors.

In electronic devices producing, Bnsz is used in warm sinks. It efficiently moves warmth away from components. This avoids getting too hot. It additionally insulates circuits, reducing short-circuit risks. Tools like power components and LED systems take advantage of its security.

Aerospace applications rely on Bnsz for thermal protection systems. It holds up against severe temperature levels throughout flight. Its lightweight nature helps in reducing gas intake. Structural stability under stress is another benefit. Engine components and rocket nozzles often utilize this material.

Metallurgical processes utilize Bnsz as a crucible material. It deals with liquified steels without wearing away. High thermal shock resistance makes sure longevity. This boosts heating system efficiency and item high quality. Steel spreading and alloy production see fewer flaws with Bnsz.

Semiconductor manufacturing relies on Bnsz for wafer processing. It gives a non-reactive surface area. This protects against contamination during production. Constant efficiency at high temperatures is important right here. It makes certain specific layering in microchips and sensors.

Chemical processing devices utilizes Bnsz for lining activators. It resists harsh materials. This expands tools life expectancy. Safety and security in severe atmospheres is enhanced. Acid handling and high-pressure reactions end up being more reputable.

Clinical tool makers use Bnsz in high-temperature tools. It makes certain accuracy and integrity. Biocompatibility makes it risk-free for surgical tools. Sanitation procedures do not weaken its residential properties. Oral implants and laser surgical procedure devices frequently integrate this material.

Renewable energy systems like photovoltaic panels utilize Bnsz for insulation. It manages warmth in photovoltaic cells. This improves power conversion rates. Long-term direct exposure to sunlight does not compromise its efficiency.

Automotive industries incorporate Bnsz right into electric vehicle batteries. It regulates temperature throughout charging. This avoids thermal runaway. Battery life and security boost considerably.

The product’s versatility originates from its distinct structure. Boron nitride supplies chemical inertness. Ceramic ingredients boost mechanical stamina. With each other, they develop a service for high-performance settings.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Precision Insulation Boron Nitride Composite Ceramic Bnsz

What is High Precision Insulation Boron Nitride Composite Ceramic Bnsz?

This material combines boron nitride with ceramics. It offers excellent thermal insulation, electrical resistance, chemical stability. It works in high-temperature, corrosive environments. Industries like aerospace, electronics, metallurgy use it for insulation parts.

What applications suit Bnsz Composite Ceramic?

It fits high-temperature furnaces, semiconductor manufacturing, molten metal handling. It insulates heating elements, protects sensitive parts. Its low thermal expansion prevents cracking under heat shifts. It resists chemicals, making it good for labs, industrial reactors.

How does Bnsz handle extreme temperatures?

It works from -200°C to 1800°C. The boron nitride matrix spreads heat evenly. This stops hot spots, reduces thermal stress. It keeps strength, shape even after repeated heating, cooling. It outperforms traditional ceramics in long-term high-heat use.

Can Bnsz parts be customized?

Yes. Manufacturers shape it into tubes, plates, crucibles, custom geometries. CNC machining ensures tight tolerances. Sizes vary from thin films to large industrial components. Customizing surface finishes, porosity levels is possible for specific needs.

Is Bnsz safe for electronic applications?

Yes. It insulates electricity, resists arcing. It doesn’t conduct current even at high voltages. Its purity prevents contamination in semiconductor processes. It shields sensitive electronics from heat, sparks. It meets safety standards for aerospace, power generation systems.

(High Precision Insulation Boron Nitride Composite Ceramic Bnsz)

REQUEST A QUOTE

RELATED PRODUCTS

Hot Press Boron Nitride Ceramic Sheet Pyrolytic Boron Nitride PBN Plate / Substrate / Wafer

Micron HBN Powder Abrasvies of the of High-purity Hexagonal Boron Nitride White Powder Ceramic Hbn 25 Kg 2.29g/cm

High Purity 99% Insulator Hexagonal Boron Nitride Ceramic Parts Boron Nitride Rod Tube Plate Disc for PVD and Plasma Systems

High Purity BN Ceramic Boron Nitride Crucible for Melting

High Temperature BN Composite Boron Nitride Ceramic Crucible Part