Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Boron Nitride Ceramic

Boron Nitride (BN) ceramic is a unique material renowned for its exceptional properties, making it highly valuable in various industrial applications. It exists in multiple forms, primarily hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride (w-BN). Hexagonal BN, the most common form, is often compared to graphite due to its lubricious and thermally conductive yet electrically insulating nature. Boron Nitride ceramics are synthesized under high temperatures and pressures, offering a rare combination of properties not found in many other materials.

Features of Boron Nitride Ceramic

Thermal Conductivity: Excellent thermal conductivity, especially in the hexagonal form, allowing efficient heat dissipation.

Electrical Insulation: Outstanding electrical insulation properties make it ideal for electrical applications requiring thermal management.

Chemical Stability: Highly resistant to chemical attacks, including strong acids and bases, ensuring durability in harsh environments.

Thermal Shock Resistance: Superior resistance to thermal shock, enabling it to withstand rapid temperature changes without cracking.

Mechanical Strength: Good mechanical strength at both room and elevated temperatures, although this can vary with the form of BN.

Lubricity: Self-lubricating property due to its layered structure, which reduces friction and wear in moving parts.

Non-Toxic: Safe to use in various settings, including medical and food processing industries, due to its non-toxic nature.

High-Temperature Performance: Maintains stability at extremely high temperatures, exceeding 1000°C in inert atmospheres, making it suitable for refractory applications.

(High Purity 99% Boron Nitride Advanced Composite Pipe BN Ceramic Heat Shield Tube)

Specification of High Purity 99% Boron Nitride Advanced Composite Pipe BN Ceramic Heat Shield Tube

The High Purity 99% Boron Nitride Advanced Composite Pipeline BN Ceramic Heat Shield Tube is made for requiring high-temperature applications. This item makes use of boron nitride ceramic with a pureness degree of 99%. It takes care of extreme warmth well. The product stays stable in atmospheres up to 1800 ° C. It resists sudden temperature modifications well. This stops fractures or damage during fast home heating or cooling. The composite framework integrates boron nitride with reinforcing representatives. This boosts mechanical toughness without compromising thermal efficiency. The ceramic tube works in aerospace, metallurgy, and semiconductor sectors. It protects delicate elements from warm damage. The material has low thermal expansion. It keeps its shape under extreme warmth. High thermal conductivity permits reliable heat distribution. This minimizes hot spots. Television withstands chemical reactions with molten metals, acids, and antacid. It remains undamaged in harsh setups. Electrical insulation buildings avoid present leak. This makes certain security in digital applications. The smooth surface area lessens friction. It minimizes wear throughout procedure. The tube is simple to machine. Custom-made sizes and shapes are possible. Standard dimensions include outer diameters from 10mm to 200mm. Wall surface density ranges from 2mm to 20mm. Sizes reach up to 1000mm. The lightweight style cuts energy usage. It simplifies taking care of and installation. The ceramic tube surpasses typical materials like graphite or alumina. It lasts longer under comparable problems. Marginal upkeep is required. This saves time and expenses. The product satisfies rigorous market standards. Quality checks guarantee uniformity. Custom options are available for special demands. The BN ceramic heat shield tube is trusted for thermal monitoring. It works in furnaces, reactors, and sophisticated equipment. The product withstands oxidation in air. It carries out well in inert gases or vacuum.

(High Purity 99% Boron Nitride Advanced Composite Pipe BN Ceramic Heat Shield Tube)

Applications of High Purity 99% Boron Nitride Advanced Composite Pipe BN Ceramic Heat Shield Tube

High Pureness 99% Boron Nitride Advanced Composite Pipeline BN Ceramic Heat Shield Tube offers important roles in markets needing severe heat resistance. The material combines boron nitride ceramic with advanced compounds. This produces an item efficient in handling temperatures over 2000 ° C without breaking down. It stands up to thermal shock, maintains toughness under stress, and stays steady in destructive settings. These attributes make it ideal for high-performance applications.

In aerospace, the tube serves as a heat shield for rocket engines and exhaust systems. It shields sensitive components from extreme warmth during launches. It also minimizes weight contrasted to traditional steel guards. This boosts fuel performance and haul capacity. The electric insulation properties prevent brief circuits in digital parts near warm sources.

Semiconductor producing uses television in high-temperature heating systems. It holds silicon wafers during processes like chemical vapor deposition. The material does not respond with chemicals. This keeps production environments tidy. It ensures constant top quality in chip construction.

Metallurgical industries count on television for taking care of molten steels. It lines crucibles and transfer pipelines. The non-wetting surface area quits metal attachment. This expands tools life and minimizes downtime. The low thermal growth prevents breaking throughout fast temperature level changes.

Power industries use television in nuclear reactors and solar thermal systems. It shields activator components, improving safety. In solar arrangements, it focuses heat efficiently. This increases power conversion prices.

Laboratories make use of television for high-heat experiments. It safely includes reactions involving plasma or lasers. The smooth surface area stands up to wear. This decreases contamination risks in sensitive tests.

The product’s flexibility comes from its purity and composite layout. It works where metals or basic ceramics fail. Customers benefit from longer-lasting components, reduced upkeep, and higher process efficiency.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Purity 99% Boron Nitride Advanced Composite Pipe BN Ceramic Heat Shield Tube

High Purity 99% Boron Nitride Advanced Composite Pipe BN Ceramic Heat Shield Tube FAQs

What is boron nitride? Boron nitride (BN) is a synthetic ceramic material. It combines boron and nitrogen atoms. The hexagonal structure resembles graphite. It offers high thermal stability, low friction, and excellent electrical insulation. The advanced composite pipe uses 99% pure BN for superior performance.

What makes this heat shield tube unique? The tube is made with 99% pure boron nitride. This ensures minimal impurities. It handles extreme temperatures up to 2000°C in inert environments. It resists thermal shock better than traditional ceramics. The material does not react with molten metals or corrosive gases. This makes it ideal for harsh industrial settings.

Where is this product used? Common applications include aerospace components, semiconductor manufacturing, and metal casting. It shields equipment from high heat in furnaces or reactors. It protects sensors in high-temperature environments. Electronics use it for insulation in high-power devices. Its lightweight nature suits applications where weight matters.

How do I install and maintain the tube? Handle the tube carefully to avoid cracks. Use tools designed for brittle materials. Clean surfaces before installation. Ensure proper alignment to prevent stress during operation. Check for wear or damage after exposure to extreme conditions. Replace the tube if surface cracks or erosion appear. Store it in a dry environment to avoid moisture absorption.

How does it compare to other heat-resistant materials? Traditional ceramics like alumina crack under rapid temperature changes. Metals oxidize or melt at lower temperatures. Boron nitride maintains strength under thermal stress. It outperforms graphite in oxidation resistance. The purity level reduces gas emissions during high-heat use. This makes it safer for vacuum or controlled environments.

(High Purity 99% Boron Nitride Advanced Composite Pipe BN Ceramic Heat Shield Tube)

REQUEST A QUOTE

RELATED PRODUCTS

99.8% 100-200nm Hexagonal Boron Nitride Powder Nano Boron Nitride Powder Ceramic Raw Materials Additive Lubricant

Composite Material Boron Nitride+Silicon Nitride Ceramic BN+Si3N4 Break Ring

Boron Nitride Rings High Temperature Resistant Customized Insulation BN Ceramic Ring Part

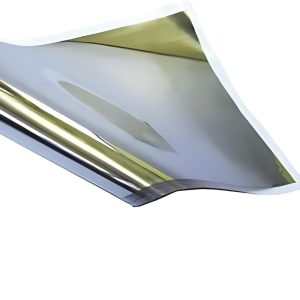

Chemically Stable Boron Nitride Ceramic BN Film

HRB HBN Ceramic Hexagonal Boron Nitride Powder