Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

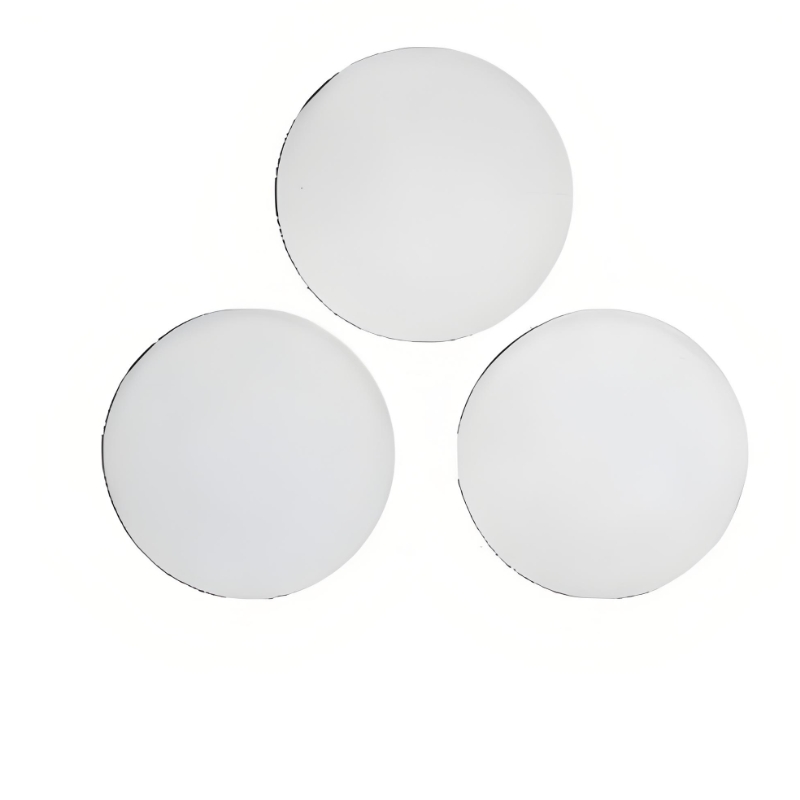

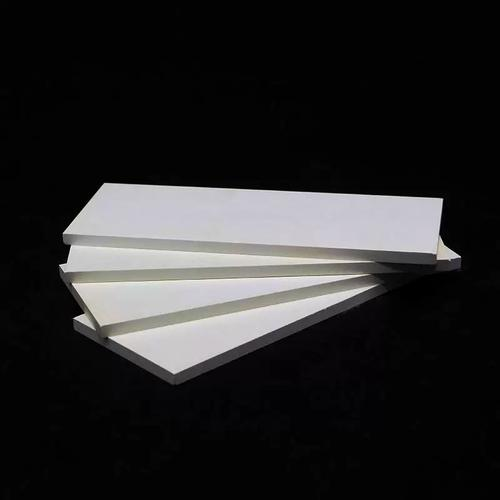

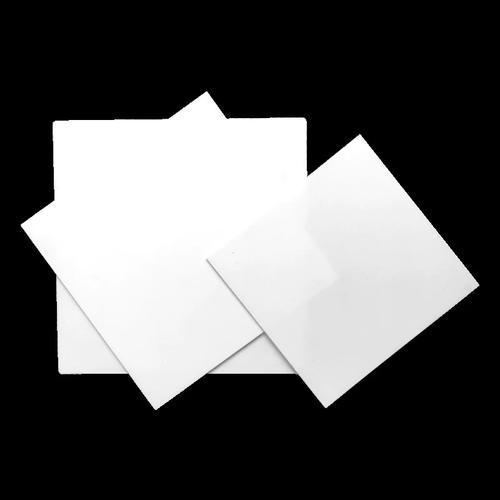

Overview of Boron Nitride Plate:

Boron nitride (BN) plates are solid forms of boron nitride that can be produced in various crystal structures, most commonly hexagonal boron nitride (h-BN), which is often referred to as “white graphene” due to its layered structure similar to graphite. These plates offer a range of exceptional properties that make them valuable in numerous applications across different industries.

Features of Boron Nitride Plate:

1. High Thermal Conductivity:

The high thermal conductivity of BN boards, especially along the plane of the h-BN layer, makes them ideal for heat dissipation and thermal management applications.

2. Excellent Electrical Insulation:

In addition to high thermal conductivity, BN boards are also strong electrical insulators, which is critical for many electronic applications.

3. Chemical Stability:

BN plates have excellent chemical resistance, even at high temperatures, resulting in durability in corrosive environments.

4. Mechanical Strength:

They have good mechanical strength and hardness, especially cubic boron nitride (c-BN), which is second only to diamond.

5. Optical transparency:

h-BN plates are transparent to UV, visible and infrared light, making them suitable for optical applications.

6. Low coefficient of thermal expansion (CTE):

BN has a low coefficient of thermal expansion (CTE), which helps prevent thermal shock and cracking under temperature changes.

7. Lubricity:

The layered structure of h-BN provides excellent lubricity, especially in vacuum or inert environments where conventional lubricants cannot be used.

8. Wide bandgap:

BN has a wide bandgap, making it suitable for high power and high frequency electronics.

Specifications of Boron Nitride Plate:

| Property | Specification/Value | Notes |

| Thermal Conductivity | Up to ~300 W/m·K (in-plane for h-BN) | Highly dependent on crystal orientation and purity. |

| Electrical Resistivity | > 10^12 Ω·cm | Excellent electrical insulation property. |

| Dielectric Constant | ~4-6 (for h-BN) | Low dielectric constant reduces parasitic capacitance. |

| Coefficient of Thermal Expansion (CTE) | ~2.5 × 10^-6/K (for h-BN) | Similar CTE to silicon, beneficial for semiconductor applications. |

| Hardness | Vickers hardness up to ~45 GPa (for c-BN) | High hardness, especially cubic BN, second only to diamond. |

| Melting Point | ~3000°C | High melting point contributes to thermal stability. |

| Chemical Stability | Stable in many acids and bases at high temperatures | Exceptional resistance to chemical attack. |

| Optical Transparency | Transparent from UV to IR | Particularly useful for optical applications. |

| Friction Coefficient | As low as ~0.16 (for h-BN) | Makes it suitable for lubrication in vacuum or inert environments. |

| Band Gap | ~5.9 eV (for h-BN) | Wide bandgap material suitable for high-power and high-frequency devices. |

| Density | ~2.27 g/cm³ (for h-BN) | Lower density compared to many ceramics. |

| Flexural Strength | Up to ~400 MPa | Good mechanical strength suitable for various applications. |

| Porosity | Typically < 1% | Low porosity ensures high density and strength. |

| Maximum Operating Temperature | Up to 1000°C in air, higher in inert atmospheres | Can withstand extreme temperatures with minimal degradation. |

| Thermal Shock Resistance | Good | Resistant to cracking under rapid temperature changes. |

| Lubricity | Excellent dry lubricant | Layered structure allows for easy sliding of layers. |

Manufacturing Methods

| Method | Description | Applications |

| Hot Pressing | Powder is pressed and heated simultaneously. | Produces dense, uniform plates for high-strength applications. |

| Sintering | Heating BN powder without melting, allowing particles to bond. | Suitable for complex shapes and large components. |

| Chemical Vapor Deposition (CVD) | BN vapor deposited onto a substrate to form a plate. | Ideal for thin films and coatings requiring precise control. |

| Pressureless Sintering | Creates BN parts without external pressure. | Useful for creating intricate or non-uniform shapes. |

Environmental Considerations

| Aspect | Description | Notes |

| Material Source | Boron sourced from borate minerals; nitrogen abundant. | Extraction impacts generally less severe than for metals. |

| Production Energy | Processes can be energy-intensive but are continuously optimized. | Efforts to minimize environmental impact through efficiency improvements. |

| Recycling Potential | Not widely established but materials are not hazardous. | Ongoing research into recycling technologies. |

| Disposal | Non-toxic and stable; does not decompose into harmful substances. | Safe disposal options available. |

Applications of Boron Nitride Plate:

1. Thermal Management

Heat Sinks: BN plates are used as efficient heat sinks in electronics to dissipate heat from components like CPUs, GPUs, and power transistors.

Thermal Interface Materials (TIMs): Employed between heat-generating electronic components and heat dissipation devices to improve thermal performance.

2. Electronics and Semiconductors

Substrates: Used as substrates for semiconductor devices, especially in high-power and high-frequency applications.

Insulating Layers: Provide electrical insulation while allowing efficient heat conduction in semiconductor packaging.

Gate Dielectrics: Utilized in MOSFETs and other transistors to reduce parasitic capacitance and improve switching speeds.

3. Optoelectronics

LED Substrates: BN plates can be used as a substrate or buffer layer for GaN-based LEDs to improve efficiency and reduce defect density.

Photodetectors and solar cells: Good optical transparency and stability under harsh conditions.

4. Catalysis

Catalyst Supports: Provide a stable platform for catalyst particles in various chemical reactions, particularly in high-temperature processes.

Electrocatalysis: Used in electrochemical cells for energy conversion and storage systems.

5. Surface Coatings

Wear Resistance: Applied to surfaces to enhance wear resistance and durability.

Friction Reduction: Utilized as solid lubricants in vacuum or inert environments where traditional lubricants cannot be used.

Corrosion Protection: Provides protection against corrosion in aggressive environments.

6. Cutting Tools and Machining

Tool Coatings: Applied to cutting tools and machining components to increase durability and reduce wear.

Molds and Dies: Used as coatings on molds and dies to improve release properties and extend tool life.

7. Automotive and Aerospace

Power Electronics: Critical for electric and hybrid vehicles where efficient thermal management is necessary for power modules and inverters.

Radiation Shielding: Provides effective shielding against radiation in spacecraft components.

High-Temperature Components: Suitable for parts exposed to extreme temperatures, such as engine components and exhaust systems.

8. Energy Storage

Battery Electrode: BN coated electrode can form a stable interface between electrolyte and electrode material, thus improving battery performance and safety.

Fuel Cell: Used as gas diffusion layer and catalyst carrier.

9. Biomedical Applications

Medical Implants: Used for biocompatible coatings on implants or devices due to their non-reactive nature.

Drug Delivery Systems: Nanoparticles of BN can be functionalized for targeted drug delivery.

10. Manufacturing and Machining

High Temperature Molds: For manufacturing processes involving high temperatures, such as metal casting and molding.

Precision Parts: For precision engineering applications requiring high thermal stability and low CTE.

11. Research and Development

Advanced Materials Development: Research and development of new materials with application-specific properties.

Nanotechnology: Exploring the unique quantum properties of nanoelectronic and optoelectronic devices. 12.

12. Consumer Electronics

Heat Sinks and Thermal Interfaces: Critical to heat management in consumer electronics devices such as smartphones, laptops, and game consoles.

13. Chemical Processing

Reactor Linings: Used in reactors where high temperatures and corrosive chemicals are present.

Heat Exchangers: Utilized in industrial processes involving heat transfer at high temperatures.

14. Space Exploration

Thermal Control Systems: BN plates help manage thermal conditions in spacecraft, ensuring reliable operation in space.

Extreme Environment Components: Used in equipment designed to operate under extreme temperatures and pressures encountered in space missions.

Company Profile

Advanced Ceramics founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2012, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Aluminum Nitride Ceramic Products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

FAQs of Boron Nitride Plate

1. What is a boron nitride Plate?

A: A boron nitride (BN) plate is a solid form of boron nitride, typically manufactured as a flat, rigid sheet or block. Boron nitride exists in several crystal structures, but the most common for plates is hexagonal boron nitride (h-BN), which has a layered structure similar to graphite and is sometimes referred to as “white graphene.” Cubic boron nitride (c-BN) is another form that exhibits extremely high hardness, second only to diamond.

2. What are the benefits of boron nitride Plate?

A: Boron nitride (BN) plates offer a multitude of benefits that make them highly valuable across various industries. Here are the key advantages: High Thermal Conductivity, Excellent Electrical Insulation, Chemical Stability, Wide Bandgap, Environmental Stability, Biocompatibility.

3. What industries use boron nitride Plate?

A: Boron nitride (BN) plates, due to their exceptional properties, find applications across a wide range of industries. Such as electronics and semiconductors, optoelectronics, automotive, energy storage, manufacturing and machining, chemical processing, catalysis.

4. Can boron nitride Plates be used in high-temperature environments?

A: Yes, boron nitride (BN) plates are exceptionally well-suited for use in high-temperature environments. Boron nitride has a very high melting point, around 3000℃ (5432℉). This makes it suitable for applications that involve exposure to extreme temperatures.

5. Are boron nitride Plates environmentally friendly?

A: Boron nitride (BN) plates generally exhibit characteristics that can be considered environmentally friendly, but the overall environmental impact depends on several factors, including the manufacturing process, use phase, and end-of-life disposal or recycling.

REQUEST A QUOTE

RELATED PRODUCTS

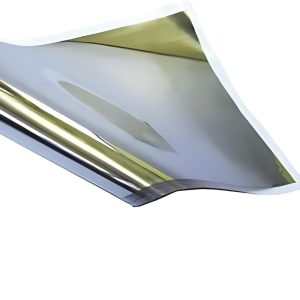

Hot Press Boron Nitride Ceramic Sheet Pyrolytic Boron Nitride PBN Plate / Substrate / Wafer

Chemically Stable Boron Nitride Ceramic BN Film

High temperature high purity 99% BN boron nitride crucible

Hexagonal Boron Nitride Tube Boron Nitride Ceramic Parts

High Working Temperature Corrosion Resistance Boron Nitride Gasket