Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Boron Nitride Ceramic

Boron Nitride (BN) ceramic is a unique material renowned for its exceptional properties, making it highly valuable in various industrial applications. It exists in multiple forms, primarily hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride (w-BN). Hexagonal BN, the most common form, is often compared to graphite due to its lubricious and thermally conductive yet electrically insulating nature. Boron Nitride ceramics are synthesized under high temperatures and pressures, offering a rare combination of properties not found in many other materials.

Features of Boron Nitride Ceramic

Thermal Conductivity: Excellent thermal conductivity, especially in the hexagonal form, allowing efficient heat dissipation.

Electrical Insulation: Outstanding electrical insulation properties make it ideal for electrical applications requiring thermal management.

Chemical Stability: Highly resistant to chemical attacks, including strong acids and bases, ensuring durability in harsh environments.

Thermal Shock Resistance: Superior resistance to thermal shock, enabling it to withstand rapid temperature changes without cracking.

Mechanical Strength: Good mechanical strength at both room and elevated temperatures, although this can vary with the form of BN.

Lubricity: Self-lubricating property due to its layered structure, which reduces friction and wear in moving parts.

Non-Toxic: Safe to use in various settings, including medical and food processing industries, due to its non-toxic nature.

High-Temperature Performance: Maintains stability at extremely high temperatures, exceeding 1000°C in inert atmospheres, making it suitable for refractory applications.

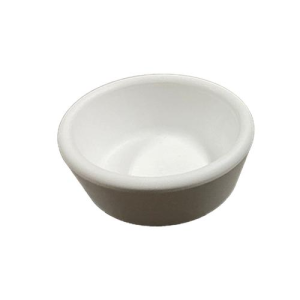

(High Temperature BN Composite Boron Nitride Ceramic Crucible Part)

Specification of High Temperature BN Composite Boron Nitride Ceramic Crucible Part

The High Temperature BN Compound Boron Nitride Ceramic Crucible Component is designed for extreme warm applications. It takes care of temperatures as much as 1800 ° C in inert ambiences. The material stands up to thermal shock, maintaining architectural integrity throughout fast temperature level changes. It shows high chemical stability, avoiding reactions with molten metals, acids, or antacid. This crucible offers superb thermal conductivity, guaranteeing also warmth circulation. It remains electrically shielding, stopping short circuits in high-temperature procedures.

The crucible includes a dense, low-porosity structure. This minimizes material adherence, simplifying cleansing. The smooth surface coating lowers rubbing, protecting sensitive materials. Boron nitride composite building and construction guarantees light-weight resilience. It outperforms standard porcelains like alumina or quartz in thermal and mechanical performance.

Applications consist of steel melting, semiconductor processing, and aerospace component manufacturing. It deals with gold, silver, platinum, light weight aluminum, and alloys. The crucible fits vacuum atmospheres and inert gas heaters. It serves labs, commercial shops, and progressed product research study centers.

Criterion dimensions vary from 50ml to 2000ml capacity. Custom dimensions fit certain requirements. Wall surface density ranges 3mm and 10mm, balancing stamina and warm transfer. Running temperatures span 800 ° C to 1800 ° C relying on problems. Thermal conductivity gets to 25-30 W/m · K, going beyond most porcelains. Volume resistivity goes beyond 10 ^ 14 Ω · cm at heats.

The product resists oxidation approximately 1000 ° C in air. It maintains reduced wettability versus liquified steels, decreasing contamination dangers. Machinable pre-sintered spaces permit custom shaping. Non-reactive buildings guarantee pureness in sensitive procedures like crystal growth.

Service life surpasses conventional graphite crucibles under comparable conditions. Marginal deterioration takes place after repeated thermal cycles. Compatibility with induction heater improves versatility. The crucible meets ASTM standards for high-purity ceramic components.

Product packaging consists of safety foam inserts to stop transportation damages. Managing standards emphasize staying clear of mechanical effect on brittle edges. Storage suggestions recommend dry problems to maintain material stability.

(High Temperature BN Composite Boron Nitride Ceramic Crucible Part)

Applications of High Temperature BN Composite Boron Nitride Ceramic Crucible Part

High-temperature BN composite boron nitride ceramic crucible parts serve essential functions in industries requiring severe heat resistance and chemical stability. These crucibles handle temperature levels above 2000 ° C without breaking down. They are suitable for melting and handling metals like aluminum, magnesium, and uncommon planet alloys. Their non-wetting surface area protects against molten metals from sticking, making certain tidy puts and marginal product loss.

In semiconductor manufacturing, BN composite crucibles are important for growing single crystals and generating high-purity products. The ceramic’s reduced thermal growth minimizes fracturing under fast temperature level shifts. It stands up to responses with acidic or alkaline materials, keeping purity in delicate processes. This makes them dependable for developing silicon wafers and gallium arsenide components.

The solar energy industry makes use of these crucibles for refining silicon utilized in solar batteries. The material’s high thermal conductivity makes certain also heat distribution during silicon melting. It holds up against extended exposure to thaw silicon without contamination, boosting cell performance.

Aerospace applications benefit from BN composite crucibles in generating heat-resistant alloys and coatings. The crucibles survive extreme conditions in generator blade manufacturing and various other high-stress components. Their lightweight nature lines up with aerospace demands for durable yet low-mass materials.

Chemical labs depend on these crucibles for analyzing destructive substances. They resist assault from changes and molten salts, ensuring exact examination outcomes. Their electrical insulation properties protect against interference in experiments entailing conductive products.

BN composite crucibles are additionally utilized in glass handling. They keep architectural integrity when holding molten glass, avoiding defects triggered by pollutants. The product’s smooth surface enables easy release of cooled glass products.

These crucibles sustain atomic energy study by securely consisting of contaminated products throughout high-temperature experiments. Their radiation resistance and security under vacuum cleaner or inert gas settings make them suitable for advanced reactor studies.

Durability and marginal upkeep lower functional downtime. The crucibles’ long life span lowers substitute expenses, supplying value across commercial and scientific areas. Their convenience in severe environments places them as crucial tools for progressing product science and manufacturing technologies.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Temperature BN Composite Boron Nitride Ceramic Crucible Part

High Temperature BN Composite Boron Nitride Ceramic Crucible Part FAQs

What is the maximum temperature this crucible can handle?

The crucible works in temperatures up to 2000°C in inert gas or vacuum environments. It resists thermal shock. In air or oxygen-rich settings, the limit drops to 800-1000°C. Oxidation occurs above this range.

What industries use this product?

It suits labs, semiconductor manufacturing, metal processing, and high-purity material production. Common applications include melting metals, growing crystals, and handling corrosive chemicals. It performs well in extreme heat and resists chemical reactions.

How should the crucible be stored and handled?

Keep it dry and clean. Avoid bumping or dropping it. The material is strong but brittle. Use gloves to prevent oil or dirt from touching the surface. Store it in a padded container if not used for long periods.

Does the crucible wear out over time?

Its lifespan depends on usage conditions. Frequent exposure to extreme heat or harsh chemicals may cause slow degradation. Proper care reduces wear. Inspect it regularly for cracks or surface changes. Replace it if performance drops.

How do I clean the crucible after use?

Remove residues with mild acids or alkalis based on the material processed. Avoid abrasive tools. Rinse with distilled water. Dry it completely before reuse. Do not expose it to sudden temperature changes during cleaning.

(High Temperature BN Composite Boron Nitride Ceramic Crucible Part)

REQUEST A QUOTE

RELATED PRODUCTS

Corrosion Resistant Aluminum Nitride Composite Boron Nitride Ceramic Part AIN Ceramic Plate

99% Hexagon Hbn Boron Nitride Bn Ceramic Tube Rod Pipe

High temperature high purity 99% BN boron nitride crucible

” Ceramics” Hot Pressed Boron Nitride BN Ceramic Nozzle Tube

Hot Pressed BN Ceramic Insulation Tube Boron Nitride Seal Ring Solid Roller Cylinder Ring