Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Quartz Ceramic Products

Quartz ceramic, also known as fused quartz ceramic or pure silicon ceramic, is an advanced ceramic material made of pure silicon dioxide (SiO₂). It is made by melting high-purity quartz sand at high temperature and then cooling and solidifying it. It has unique physical and chemical properties, making it an ideal choice for many high-tech applications. Quartz ceramic products are widely used in semiconductor manufacturing, optics, electronics, chemical industry and high-temperature industries.

Characteristics and advantages of quartz ceramics

Extremely high thermal stability: Quartz ceramics can remain stable under extreme temperature conditions. They are not only resistant to high temperatures, but also show excellent thermal shock resistance in rapid temperature changes.

Low thermal expansion coefficient: Due to its low thermal expansion coefficient, quartz ceramics have good dimensional stability when the temperature changes and are not easy to deform or crack.

Excellent electrical insulation: Provides excellent electrical insulation performance and is suitable for applications requiring high voltage isolation.

High transparency: It has good light transmittance in a wide band from ultraviolet to infrared, and is particularly suitable for applications such as optical windows and lenses.

Chemical stability: Excellent resistance to most acids, alkalis and other corrosive substances, and almost unaffected by other chemicals except hydrofluoric acid and phosphoric acid.

Mechanical strength: Although quartz ceramic is not as hard as some other types of ceramics, it still has enough mechanical strength to meet the needs of many application scenarios.

High UV transmittance: It has high transmittance in the ultraviolet region, which makes it very useful in UV curing equipment and UV spectrometers.

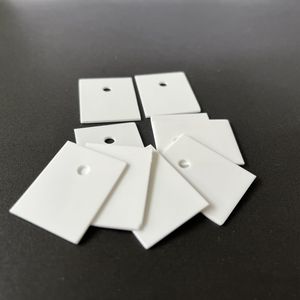

(Ceramic Silica Quartz Crucible Bowl for Melt Gold Silver Copper Platinum Jewelry Tool with Metal Boat Pot)

Specifications of Ceramic Silica Quartz Crucible Bowl for Melt Gold Silver Copper Platinum Jewelry Tool with Metal Boat Pot

The Ceramic Silica Quartz Crucible Bowl is developed for melting rare-earth elements like gold, silver, copper, and platinum. It benefits precious jewelry making, lab experiments, or commercial refining. The dish is made from high-purity ceramic silica quartz. This material ensures resistance to extreme warm and chemical corrosion. It deals with temperature levels up to 1600 ° C without splitting or weakening. The framework is dense and non-porous. This protects against steel absorption and contamination. It keeps melted steels pure throughout duplicated usages.

The crucible dish has a smooth indoor surface area. This allows simple putting and minimizes material deposit. It is formed for stability in heaters or lantern arrangements. The thick wall surfaces provide also warmth distribution. This minimizes hot spots and improves melting efficiency. The dish stands up to thermal shock. Fast temperature changes do not harm it. Customers can warm or cool it swiftly without breaking risks.

This item works with induction heating systems, gas lanterns, or electrical melters. It comes in multiple dimensions. Typical alternatives consist of 10ml, 25ml, 50ml, and 100ml capacities. Custom-made dimensions are available for certain needs. The design consists of a tapered rim. This avoids spills and boosts taking care of with tongs.

The ceramic silica quartz product is more challenging than graphite or clay crucibles. It lasts longer under frequent use. It resists acids, antacid, and metal slag. This makes it ideal for varied alloys and procedures. The bowl is lightweight but strong. It does not react with liquified steels. This makes sure consistent results in time.

Upkeep is straightforward. Tidy the bowl after each usage with a soft brush or non-abrasive tool. Stay clear of abrupt effects or going down. Store it in a dry area to prevent wetness absorption. Pre-heating the crucible prior to very first usage is advised. This gets rid of any type of residual contaminations.

The crucible is suitable for jewelry experts, metalworkers, and labs. It meets specialist requirements for precision and toughness. Its recyclable nature reduces waste and price. Correct treatment extends its life expectancy significantly.

(Ceramic Silica Quartz Crucible Bowl for Melt Gold Silver Copper Platinum Jewelry Tool with Metal Boat Pot)

Applications of Ceramic Silica Quartz Crucible Bowl for Melt Gold Silver Copper Platinum Jewelry Tool with Metal Boat Pot

Ceramic silica quartz crucible bowls serve essential duties in melting gold, silver, copper, platinum, and other steels for fashion jewelry production. These devices take care of severe warm without breaking down. Their high melting factor guarantees they remain steady also under intense temperatures. This makes them optimal for repeated usage in heaters or with lanterns. The product resists thermal shock, implying abrupt temperature level adjustments will not crack them. Individuals prevent constant substitutes, conserving expenses over time.

The crucible’s chemical resistance avoids unwanted reactions with molten metals. Contaminations from containers can mess up valuable products. Silica quartz keeps melts pure, guaranteeing high-grade outcomes. Jewelers depend on this for consistent surfaces in rings, lockets, and other items. The smooth interior surface enables very easy pouring and reduces steel sticking. Cleaning up becomes easier after each usage.

The boat-shaped design boosts heat circulation. This form concentrates heat on the steel, accelerating melting. Security issues throughout putting. The vast base stops tipping, minimizing spills and waste. Safety improves throughout dealing with. These crucibles deal with induction heaters, gas lanterns, and electric kilns. Little workshops and big workshops both take advantage of their flexibility.

Durability stands apart. Ceramic silica quartz stands up to wear from continuous cooling and heating. Experts use these crucibles daily without performance loss. Maintenance is straightforward. Rinsing with water eliminates residue. Avoid unpleasant cleansers to protect the surface. Shop in dry locations to prevent dampness damages.

Applications prolong past precious jewelry. Labs use these crucibles for steel examples. Electronic devices makers thaw conductive materials for elements. Artists shaping steel sculptures locate them reputable. The convenience suits several high-temperature jobs.

These crucibles fulfill stringent industry requirements. Users trust them for accuracy and security. Purchasing quality tools boosts efficiency in metalworking. The ceramic silica quartz crucible dish continues to be a practical selection for any person managing rare-earth elements.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Ceramic Silica Quartz Crucible Bowl for Melt Gold Silver Copper Platinum Jewelry Tool with Metal Boat Pot

Ceramic silica quartz crucible bowls handle high-temperature metal melting. These bowls work for gold, silver, copper, platinum. Users often ask questions before buying. Here are common ones.

What material is the crucible made of? The crucible uses ceramic silica quartz. This mix boosts heat resistance. It prevents cracks under extreme temperatures. The material stays stable during rapid heating or cooling.

What temperature can it withstand? The crucible handles up to 2800°F (1538°C). It melts most precious metals easily. Avoid exceeding this limit. Overheating shortens its lifespan. Check your furnace or torch specs first.

How do I clean it after use? Let the crucible cool completely. Use a soft brush to remove residue. Soak it in diluted vinegar for tough stains. Never use abrasive tools. Scratches weaken the structure. Rinse with water and dry before reuse.

Does it work with induction furnaces? Yes. The material is non-conductive. It suits induction heating setups. Ensure the crucible size fits your furnace. Test stability before full use. Uneven placement risks spills or cracks.

How long does it last? Lifespan depends on usage frequency. Proper care extends durability. Avoid sudden temperature changes. Store it in a dry place. Replace it if cracks or warping appear. Regular inspection prevents accidents.

These answers cover basic concerns. Always follow safety guidelines. Match the crucible to your project needs.

(Ceramic Silica Quartz Crucible Bowl for Melt Gold Silver Copper Platinum Jewelry Tool with Metal Boat Pot)

REQUEST A QUOTE

RELATED PRODUCTS

Hot-ing Piezoelectric Ceramic Wafer Ring Excellent Long-Life Quartz P5 Material for Industrial Use Atomizing Piece

Glass Tempering Furnace Quartz Fused Silica Ceramic Roller with Good Quality

High Quality Rotating Stone Sample Ceramic Quartz Granite Artificial Stone Large Plate Ceramic Tile Display Rack

TY75345S Professional Wet Polisher to Polish Tile Slab Ceramics Porcelain Quartz Granite 4,500 Rpm M14 or M16 Spindle

OD130mm H120mm 99% High Purity Fused Quartz Silica SiO2 Ceramic Cylindrical Crucible