Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Silicon Carbide Ceramics

Silicon Carbide (SiC) ceramics are renowned for their outstanding mechanical properties, including high hardness, strength at elevated temperatures, and excellent thermal shock resistance. These materials are pivotal in cutting-edge industrial applications, from abrasives to aerospace components, due to their unique combination of properties.

Features of Silicon Carbide Ceramics

High Hardness: Exceptional wear resistance.

Thermal Shock Resistance: Can withstand rapid temperature changes.

Chemical Stability: Resistant to most chemicals.

High Thermal Conductivity: Efficient heat dissipation.

Low Density: Lightweight for its strength.

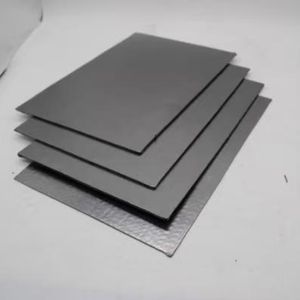

(Custom Machining Silicon Carbide Hexagonal Plate High Temperature Resistant Ceramics Purity Ceramic Parts for Welding & Cutting)

Specification of Custom Machining Silicon Carbide Hexagonal Plate High Temperature Resistant Ceramics Purity Ceramic Parts for Welding & Cutting

This item is a custom-machined silicon carbide hexagonal plate made for high-temperature applications. It is made from high-purity ceramic material. The hexagonal form makes sure even pressure distribution throughout welding and reducing procedures. The product stands up to extreme heat up to 1600 ° C without losing architectural integrity. It resists thermal shock and chemical rust. This makes it ideal for commercial settings with severe conditions. The plate is precision-engineered for tight resistances. Custom-made dimensions and densities are available to satisfy specific requirements. Silicon carbide porcelains supply outstanding wear resistance. They maintain performance under continual mechanical tension. The material’s low thermal development prevents contorting during fast temperature modifications. Its high thermal conductivity allows reliable warmth dissipation. This minimizes the threat of localized getting too hot in devices or devices. The ceramic is non-porous and chemically inert. It prevents contamination in sensitive procedures like semiconductor production or steel therapy. The surface is smooth and uniform. This decreases friction during reducing or grinding procedures. The hexagonal design supplies several contact factors. It boosts security in fixtures or equipment. Home plate works with standard welding and reducing arrangements. It works as a long lasting option to steel components susceptible to melting or contortion. Applications consist of furnace fixtures, welding nozzles, and laser cutting overviews. It is utilized in aerospace, automotive, and metal manufacture markets. The product’s pureness exceeds 99%. This makes certain very little pollutants impacting performance. Machining is done utilizing sophisticated CNC innovation. This guarantees specific edges and angles for smooth integration into existing systems. The ceramic does not call for coatings or added treatments. It runs efficiently in oxidizing or decreasing environments. Its lightweight nature decreases lots on supporting frameworks. Lengthy life span lowers replacement frequency. The product is evaluated for consistency in thickness and firmness. Custom orders consist of in-depth specs for opening patterns, edge finishes, or surface finishings. It meets industrial criteria for high-temperature ceramics. Users benefit from decreased downtime and maintenance prices. The plates are packaged safely to stop damages during delivery. Technical assistance is available for layout or application questions.

(Custom Machining Silicon Carbide Hexagonal Plate High Temperature Resistant Ceramics Purity Ceramic Parts for Welding & Cutting)

Applications of Custom Machining Silicon Carbide Hexagonal Plate High Temperature Resistant Ceramics Purity Ceramic Parts for Welding & Cutting

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Custom Machining Silicon Carbide Hexagonal Plate High Temperature Resistant Ceramics Purity Ceramic Parts for Welding & Cutting

What makes silicon carbide hexagonal plates good for high-temperature use?

Silicon carbide handles extreme heat well. It keeps its shape and strength even above 1650°C. This material resists oxidation and thermal shock. Sudden temperature changes don’t crack it. Factories and labs pick it for jobs needing long-lasting heat resistance.

How hot can these ceramic plates get before failing?

These plates work in temperatures up to 1650°C. Short-term exposure can go higher. Performance depends on purity and design. Proper use avoids cracks or warping. They’re tested in real-world settings to meet strict heat standards.

Can you make custom shapes or sizes for specific tools?

Yes. Custom machining lets you choose dimensions, hole patterns, or surface finishes. Technical drawings or samples help match exact needs. Tight tolerances ensure parts fit welding and cutting tools perfectly.

Does material purity affect performance?

Higher purity means better heat and corrosion resistance. Impurities weaken the ceramic. These plates use 99% pure silicon carbide. This boosts durability in harsh conditions like chemical exposure or repeated heating.

Why pick silicon carbide over other ceramics for welding and cutting?

It’s harder and lasts longer than alumina or zirconia. It resists wear from sparks, slag, and abrasion. Heat spreads evenly across the plate. This prevents warping during intense jobs. Factories save money with fewer replacements.

(Custom Machining Silicon Carbide Hexagonal Plate High Temperature Resistant Ceramics Purity Ceramic Parts for Welding & Cutting)

REQUEST A QUOTE

RELATED PRODUCTS

Polished High Purity Silicon Carbide Nitride Si3N4 Ceramic Rod

Silicon Carbide Sic Ceramic Refractory Plates Ceramic Sheet Wafer Carbide Tube

High Purity Silicon Carbide Fine Ball Customize Ceramic SiC Ball

Custom Made Refractory Black Sic High Temperature Resistant Silicon Carbide Ceramic Tube

Hot Silicon Carbide Ceramic Sheet Boron Carbide Ceramic Plates B4C Tiles for Sample