Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Silicon Carbide Ceramics

Silicon Carbide (SiC) ceramics are renowned for their outstanding mechanical properties, including high hardness, strength at elevated temperatures, and excellent thermal shock resistance. These materials are pivotal in cutting-edge industrial applications, from abrasives to aerospace components, due to their unique combination of properties.

Features of Silicon Carbide Ceramics

High Hardness: Exceptional wear resistance.

Thermal Shock Resistance: Can withstand rapid temperature changes.

Chemical Stability: Resistant to most chemicals.

High Thermal Conductivity: Efficient heat dissipation.

Low Density: Lightweight for its strength.

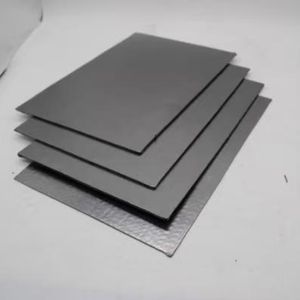

(High Refractoriness SiSiC NSiC RSiC Silicon Carbide Sic Ceramic Refractory Plates / Board /batts Kiln Setter Plate)

Specification of High Refractoriness SiSiC NSiC RSiC Silicon Carbide Sic Ceramic Refractory Plates / Board /batts Kiln Setter Plate

High Refractoriness SiSiC NSiC RSiC Silicon Carbide (SiC) Ceramic Refractory Plates, Boards, and Batts are crafted for extreme-temperature industrial applications. These plates work as kiln setter plates, racks, or supports in heating systems, kilns, and heat-treatment systems. They handle temperature levels approximately 1600 ° C in oxidizing settings and 1800 ° C in inert environments. The product resists thermal shock, mechanical anxiety, and chemical corrosion, making it excellent for repeated high-heat cycles.

Three primary qualities are available. SiSiC (sintered silicon carbide) integrates high purity with improved mechanical stamina. It suits heavy-load environments like ceramic firing or metal sintering. NSiC (nitride-bonded silicon carbide) offers premium oxidation resistance. It performs well in extended high-heat procedures, such as glass manufacturing. RSiC (reaction-bonded silicon carbide) equilibriums price and efficiency. It is dense, wear-resistant, and made use of in unpleasant problems like shops.

All qualities share essential buildings. Home plates have reduced thermal growth, decreasing warping throughout rapid temperature adjustments. They maintain architectural integrity under constant thermal stress and anxiety. Their high thermal conductivity ensures even warmth circulation, reducing energy waste. The non-porous surface area withstands slag, liquified metal, and chemical reactions. This expands life span contrasted to standard alumina or mullite plates.

Dimensions and densities are personalized. Standard thickness varies from 10mm to 50mm. Dimensions adapt to certain kiln layouts or commercial equipment. The plates are machined with precision, making certain monotony and smooth sides. This avoids damage to fragile work surfaces throughout shooting.

Applications span numerous sectors. Ceramics suppliers use them to support ceramic tiles, tableware, or technical ceramics. Metallurgical procedures count on them for sintering metal powders or heat-treating alloys. Semiconductor production uses them in diffusion heating systems. Their toughness minimizes downtime for substitutes, decreasing lasting expenses.

These SiC plates outperform standard materials. They last longer under extreme problems, need very little maintenance, and improve thermal efficiency. Custom-made options are available for specialized commercial needs.

(High Refractoriness SiSiC NSiC RSiC Silicon Carbide Sic Ceramic Refractory Plates / Board /batts Kiln Setter Plate)

Applications of High Refractoriness SiSiC NSiC RSiC Silicon Carbide Sic Ceramic Refractory Plates / Board /batts Kiln Setter Plate

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Refractoriness SiSiC NSiC RSiC Silicon Carbide Sic Ceramic Refractory Plates / Board /batts Kiln Setter Plate

What are High Refractoriness SiSiC/NSiC/RSiC Silicon Carbide Ceramic Refractory Plates?

These plates are heat-resistant materials made from silicon carbide. They come in types like reaction-bonded (RSiC), nitride-bonded (NSiC), and sintered (SiSiC). They are used in high-temperature industrial kilns as setters, shelves, or batts to hold items during firing.

Why choose silicon carbide plates over traditional refractory materials?

Silicon carbide plates handle extreme heat better. They resist thermal shock, last longer, and stay stable under rapid temperature changes. Traditional materials like alumina or firebrick crack faster or warp under similar conditions.

What temperature limits do these plates have?

They work in temperatures up to 1650°C (3000°F) depending on the type. RSiC handles slightly lower heat than NSiC or SiSiC. Exact limits vary by product grade and kiln conditions. Check manufacturer specs before use.

How long do these plates last in industrial kilns?

Lifespan depends on usage. With proper care, they last years. Avoid mechanical impacts, sudden temperature shifts, or chemical exposure. Regular inspection for cracks or wear helps extend service life.

Can these plates work with all kiln types?

They suit most kilns—electric, gas, or wood-fired. Confirm plate dimensions match kiln shelves. Ensure proper spacing for heat circulation. Some kilns need custom sizes or shapes. Ask suppliers for compatibility details.

Are silicon carbide plates cost-effective?

Initial costs are higher than basic refractory materials. Reduced replacement frequency and downtime save money long-term. They cut energy use by heating efficiently. Factor in durability and performance when budgeting.

(High Refractoriness SiSiC NSiC RSiC Silicon Carbide Sic Ceramic Refractory Plates / Board /batts Kiln Setter Plate)

REQUEST A QUOTE

RELATED PRODUCTS

Hot ing Cheap F4-F6000 Honeycomb Ceramic Filter Dust Removal Powder Siliconcarbide Black Silicon Carbide Powder for Blasting

Silicon Carbide Ceramic armor Plate

Engineering Ceramic Silicon Carbide Ceramic Bushing

Polished High Purity Silicon Carbide Nitride Si3N4 Ceramic Rod

Diamond Oil Stone CBN Stick Grinding Stone Abrasive Block Silicon Carbide Ceramic Whetstone