Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

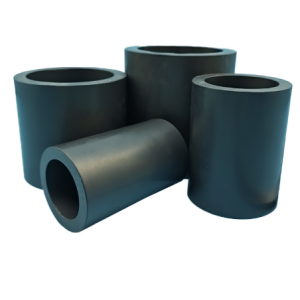

Overview of Silicon Nitride Ceramics

Silicon Nitride Ceramics are high-performance materials known for their excellent mechanical properties, including strength, toughness, and resistance to wear, corrosion, and thermal shock, making them ideal for demanding applications in various industries.

Features of Silicon Nitride Ceramics

Exceptional hardness and wear resistance.

Superior mechanical strength and fracture toughness.

Excellent thermal stability and resistance to thermal shock.

High corrosion resistance in aggressive environments.

Low density contributing to lightweight components.

(Precision CNC Machining Grey Black Silicon Nitride Si3n4 Ceramic Tube Sleeve Insert Customized)

Specifications of Precision CNC Machining Grey Black Silicon Nitride Si3n4 Ceramic Tube Sleeve Insert Customized

Precision CNC Machining Grey Black Silicon Nitride Si3N4 Porcelain Tube Sleeve Inserts deliver high-performance remedies for demanding commercial applications. These components are crafted from innovative silicon nitride ceramic, a product understood for outstanding stamina, thermal security, and resistance to wear. The grey-black pigmentation results from specialized sintering processes, improving toughness and visual consistency.

The production process uses modern CNC machining modern technology. This guarantees limited tolerances, generally within ± 0.01 mm, and precise dimensional precision. Modification is an essential feature. Clients define inner and external diameters, lengths, wall surface densities, and surface finishes to satisfy distinct job requirements. Typical coatings consist of brightened, ground, or as-machined surfaces, customized to minimize friction or improve fitment.

Silicon nitride ceramic excels in extreme atmospheres. It runs reliably in temperature levels approximately 1200 ° C without losing structural stability. The product stands up to thermal shock, making it perfect for applications involving rapid temperature adjustments. It also shows high deterioration resistance against acids, antacid, and molten metals. Electrical insulation residential or commercial properties stop existing leak, appropriate for high-voltage settings.

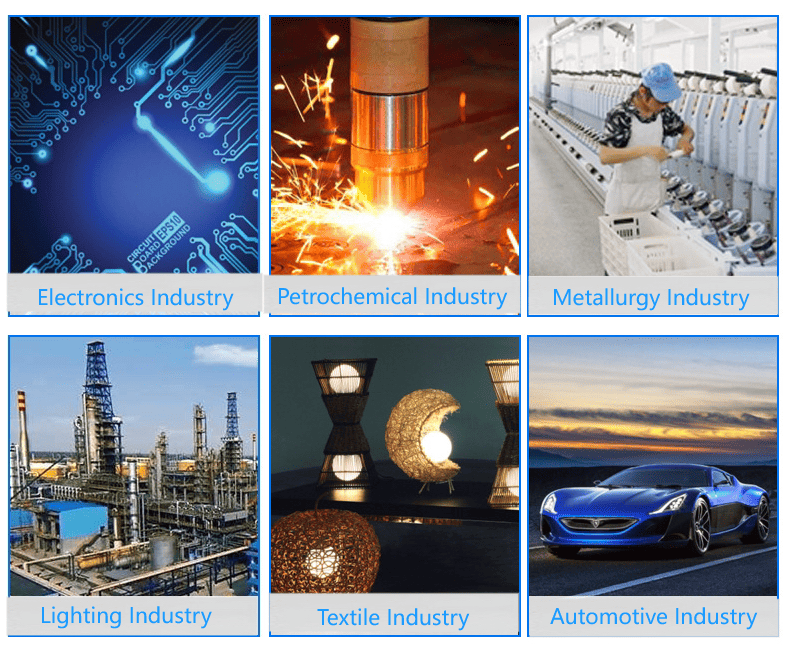

These tube sleeves are extensively made use of across markets. In aerospace, they work as protecting parts in propulsion systems. Automotive applications consist of sensors and turbocharger components. Industrial equipment gain from their use in pump seals, bearing sleeves, and reducing devices. The non-reactive nature of Si3N4 makes them suitable with harsh chemical processing settings.

Modification reaches little or big production runs. Models are available for screening and recognition. Lead times differ based on design complexity, with standard shipments within 2-4 weeks. Quality assurance entails extensive assessments making use of coordinate determining devices (CMM) and surface profilometers. Each device meets ISO 9001 criteria for uniformity and integrity.

The mix of precision machining and exceptional material buildings makes certain long service life, reduced downtime, and expense effectiveness. These ceramic tube sleeves are engineered to change metal or plastic parts where performance restrictions exist. Compatibility with high-speed turnings, heavy tons, and abrasive problems makes them a versatile selection for modern engineering difficulties.

(Precision CNC Machining Grey Black Silicon Nitride Si3n4 Ceramic Tube Sleeve Insert Customized)

Applications of Precision CNC Machining Grey Black Silicon Nitride Si3n4 Ceramic Tube Sleeve Insert Customized

Precision CNC machining creates grey black silicon nitride (Si3N4) ceramic tube sleeves for industrial applications. These parts handle severe problems. They resist heats, wear, and chemicals. Their stamina and resilience make them ideal for demanding settings. Industries like vehicle, aerospace, and production rely on these ceramic components.

Silicon nitride ceramic tubes work well in high-stress settings. They keep stability under thermal shock. Engines and generators utilize them for heat-resistant components. Semiconductor devices utilizes them for accurate, contamination-free procedures. Their electric insulation properties fit power generation systems.

CNC machining guarantees limited resistances and smooth surfaces. Custom shapes and sizes fit particular machinery requirements. Complex geometries are achievable. This adaptability supports prototyping and mass production. Makers tailor tube sleeves to client requirements.

The product’s low density reduces component weight. This improves efficiency in relocating systems. Deterioration resistance extends service life in extreme chemicals. Minimal maintenance lowers functional costs.

Medical tools utilize these porcelains for biocompatibility. They withstand sterilization without weakening. Industrial pumps and valves gain from abrasion resistance. Power industries use them in solar and nuclear systems for integrity.

Grey black silicon nitride tubes combine efficiency with flexibility. They change standard steels in sophisticated applications. Customized develops address unique difficulties. Accuracy machining warranties consistency. These features fulfill modern industry needs for efficiency and resilience.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Precision CNC Machining Grey Black Silicon Nitride Si3n4 Ceramic Tube Sleeve Insert Customized

What is a Precision CNC Machining Silicon Nitride Ceramic Tube Sleeve Insert?

This product is a custom-made ceramic part made from silicon nitride (Si3N4). It is shaped using precision CNC machining. The process ensures exact dimensions and smooth surfaces. These parts are used in high-stress environments. They handle extreme heat, wear, and corrosion better than metal or plastic.

What are the main benefits of silicon nitride ceramic sleeves?

Silicon nitride offers high temperature resistance. It works in environments up to 1200°C without losing strength. The material resists wear and chemical damage. It is lighter than metal. It reduces friction in moving parts. Electrical insulation properties make it safe for electronics.

Can these ceramic sleeves be customized?

Yes. Dimensions, shapes, and surface finishes are tailored to specific needs. CNC machining allows tight tolerances (within 0.01mm). Holes, grooves, or threads are added as required. Colors like grey or black match industrial designs. Prototypes and bulk orders are supported.

Where are these ceramic tube sleeves commonly used?

They fit industries needing durable, heat-resistant parts. Examples include aerospace engines, automotive sensors, semiconductor equipment, and medical devices. They act as insulators, bearings, or protective housings. They improve performance in harsh conditions.

How do I maintain silicon nitride ceramic sleeves?

Clean parts with non-abrasive materials to avoid scratches. Avoid sudden temperature changes to prevent cracks. Check for surface damage during use. Replace sleeves if cracks or deep wear appear. Proper handling ensures long service life.

(Precision CNC Machining Grey Black Silicon Nitride Si3n4 Ceramic Tube Sleeve Insert Customized)

REQUEST A QUOTE

RELATED PRODUCTS

Factory Direct 1.4mm-1.6mm Industrial Ceramic Beads Si3n4 Silicon Nitride Ceramic Parts Zirconia Ceramic Rod And Ball

Heat Resistant Si3N4 Silicon Nitride Ceramic Machining Part OEM Factory

Silicon Nitride Plate High Quality Si3N4 Plate Sheet Manufacturer

Silicon Nitride Nozzles High Hardness And High Strength Si3N4 Nozzles

Precision Silicon Nitride Ceramic Ball 1.3mm-2.4mm G5/ High Precision High Hardness Non-magnetic Si3N4