Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

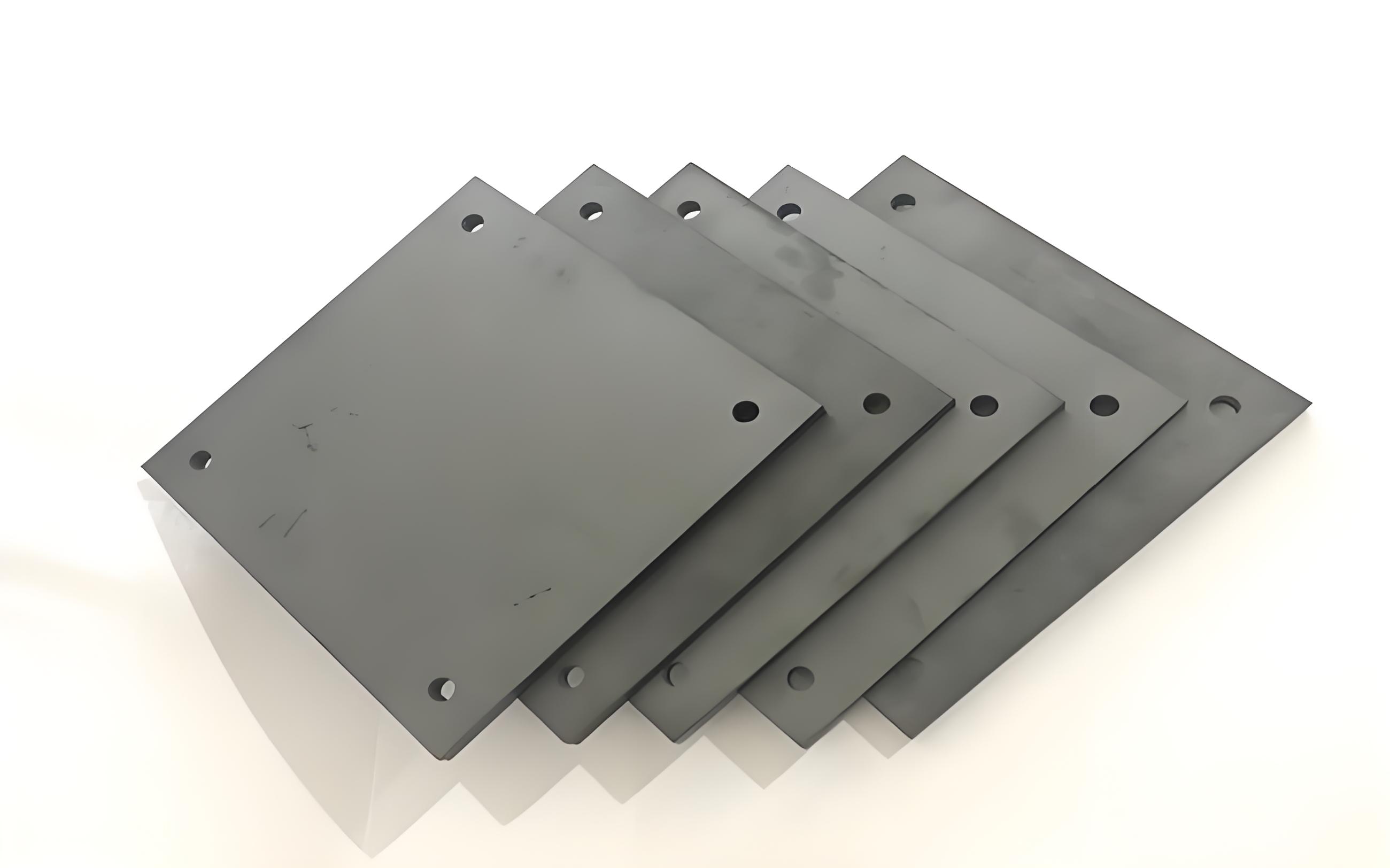

Overview of Silicon Nitride Plate

Silicon nitride (Si3N4) plates are advanced ceramic components known for their excellent hardness, high-temperature stability and corrosion resistance. Due to their excellent mechanical properties, they perform well in wear-resistant and thermal shock applications and are commonly used in bearings, cutting tools and engine components in the aerospace, automotive and manufacturing industries.

Features of Silicon Nitride Plate

High hardness and wear resistance: Exceptional hardness and excellent wear resistance make it ideal for applications requiring long-term durability in abrasive conditions.

Low density: Compared to metals and other ceramics, the density is relatively low, providing lighter components without sacrificing strength.

Excellent Fracture Toughness: Higher fracture toughness means better impact resistance and reduced likelihood of cracking under stress.

Superior Thermal Shock Resistance: Endures rapid temperature changes without degradation, suitable for environments with extreme thermal cycling.

High-Temperature Stability: Maintains mechanical properties at elevated temperatures, performing reliably up to 1200°C or more.

Chemical Inertness and Corrosion Resistance: Highly resistant to chemical attack from acids, alkalis, and molten metals, offering excellent corrosion resistance.

Self-Lubricating Properties: Inherent lubricity reduces friction, is beneficial for moving parts and leads to reduced maintenance and longer service life.

Electrical insulation: Provides good electrical insulation and is useful in applications where electrical conduction must be avoided.

Environmental compatibility: Environmentally friendly, does not contain harmful substances, suitable for various industries.

Specifications of Silicon Nitride Plate

| Property | Specification |

| Material Composition | Si₃N₄ (Silicon Nitride) |

| Density | ~3.20 g/cm³ |

| Hardness (Vickers) | ~1500-1800 HV |

| Fracture Toughness | ~6-7 MPa·m½ |

| Young’s Modulus (Elastic Modulus) | ~280-320 GPa |

| Compressive Strength | ~3000-4000 MPa |

| Flexural Strength (Bending Strength) | ~800-1000 MPa |

| Coefficient of Thermal Expansion | ~3.2 × 10⁻⁶ /°C (at room temperature to 1000°C) |

| Thermal Conductivity | ~25-35 W/m·K |

| Max Service Temperature in Air | Up to 1200°C (continuous), up to 1400°C (intermittent) |

| Chemical Resistance | Excellent resistance to acids, alkalis, and molten metals |

| Electrical Resistivity | High (>10¹² Ω·cm at room temperature) |

| Wear Resistance | Excellent, suitable for high-wear applications |

| Thermal Shock Resistance | Outstanding, capable of withstanding rapid temperature changes |

| Corrosion Resistance | Superior, especially in aggressive environments |

| Self-Lubricating Properties | Reduces friction in moving parts |

| Biocompatibility | Suitable for medical applications |

| Environmental Impact | Environmentally friendly, no harmful substances |

Silicon Nitride Plate

Applications of Silicon Nitride Plate

Aerospace Industry: Utilized in turbine engines, exhaust nozzles, and other high-temperature parts because of its outstanding thermal stability and ability to withstand thermal shock.

Automotive Industry: Applied in engine parts such as turbocharger bearings, rocker arms, and exhaust gas recirculation (EGR) valves, benefiting from low density and wear resistance.

Manufacturing and Machining: Utilized for cutting tools, grinding wheels, and wear-resistant components because of their hardness and durability.

Chemical Processing: Employed in pumps, valves, and piping systems where corrosion resistance is critical, thanks to chemical inertness.

Electronics industry: Suitable for substrates and insulators due to electrical insulation properties and thermal conductivity.

Medical devices: for surgical instruments and implants, utilizing biocompatibility and anti-sterilization.

Ceramic bearings: Preferred for applications requiring minimal lubrication and high-speed performance, such as electric motors and industrial machinery.

Semiconductor manufacturing: Use the purity and thermal stability of materials for wafer processing equipment and furnace components.

Energy sector: For fuel cells and nuclear reactors, silicon nitride’s ability to withstand extreme conditions is critical.

Company Profile

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

FAQs of Silicon Nitride plate

Q: What are the main advantages of silicon nitride plates?

A: The main advantages are high hardness, good wear resistance, low density, good fracture toughness and good thermal shock resistance. These characteristics make silicon nitride ideal for high-temperature and corrosive environments, ensuring durability and reliability.

Q: In which industries are silicon nitride plates commonly used?

A: Silicon nitride plates are widely used in aerospace, automotive, manufacturing, chemical processing, electronics, medical devices, ceramic bearings, semiconductor manufacturing and energy. Their versatility stems from their ability to withstand extreme conditions.

Q: How does silicon nitride behave at high temperatures?

A: Silicon nitride maintains its mechanical properties at high temperatures and performs reliably at temperatures of 1200°C or higher; this makes it suitable for applications where high-temperature stability is critical, such as turbine engines and exhaust systems.

Q: Is silicon nitride resistant to chemicals?

A: Yes, silicon nitride has excellent chemical inertia and corrosion resistance. It is resistant to acids, alkalis and molten metals, making it ideal for use in aggressive chemical environments such as pumps and valves.

Q: Can silicon nitride be used in medical applications?

A: Absolutely. Silicon nitride is biocompatible and resistant to sterilization processes, making it suitable for surgical instruments and implants. Its durability and inertness ensure long-term performance in medical devices.

REQUEST A QUOTE

RELATED PRODUCTS

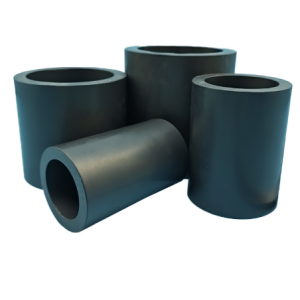

Precision CNC Machining Grey Black Silicon Nitride Si3n4 Ceramic Tube Sleeve Insert Customized

Silicon Nitride Tube High Hardness And High Strength Si3N4 Tube

Custom Good Heat Dissipation Chemical Stability Silicon Nitride Si3N4 Ceramic Part Raw Material Tube Sleeve

Super Wear Resistance Ceramic Grinding Beads 0.3mm-3.0mm Silicon Nitride Beads Industrial Si3N4 Ceramic Balls

Industrial Ceramic Bead 1.0mm Silicon Nitride Bead Custom Polished Silicon Nitride Si3N4 Ceramic Ball Grinding Ball