Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

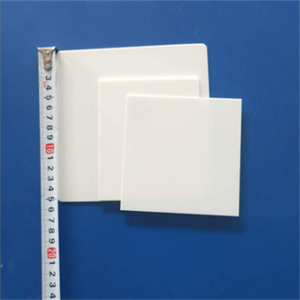

Description

Overview of Zirconium Dioxide Ceramics

Zirconium Dioxide Ceramics, known for their toughness and ability to withstand extreme temperatures, are widely used in medical, automotive, and industrial applications due to their unique properties.

Features of Zirconium Dioxide Ceramics

Exceptional fracture toughness

High thermal expansion

Excellent resistance to wear and corrosion

Biocompatibility for medical implants

(Refractory Industry Nano Ceramic Zirconia Ceramic Powder Zirconium Dioxide Zro2 Zirconia Blasting Media)

Specifications of Refractory Industry Nano Ceramic Zirconia Ceramic Powder Zirconium Dioxide Zro2 Zirconia Blasting Media

Nano Ceramic Zirconia Porcelain Powder Zirconium Dioxide Zro2 Zirconia Blasting Media is a high-performance material for commercial applications. This item is made from zirconium dioxide. It has a nano-scale bit framework. This improves its mechanical strength and longevity. The powder is perfect for usage in rough atmospheres. It functions well in high-temperature settings. It resists wear and rust successfully.

The particle size of this zirconia powder is securely regulated. It ranges from nanometers to micrometers. This enables precise application in finishes and surface therapies. The product has high pureness degrees. It exceeds 99% ZrO2 material. This ensures minimal impurities. It enhances performance in critical processes like thermal barrier coatings.

This ceramic powder has outstanding thermal stability. It can manage temperature levels approximately 2400 ° C. It maintains structural integrity under severe warmth. This makes it ideal for refractory linings in heaters. It is also utilized in aerospace components. The low thermal conductivity decreases power loss.

The hardness of zirconia blowing up media is outstanding. It rates high up on the Mohs scale. This makes it efficient for unpleasant blowing up. It cleans up and prepares surface areas without triggering damages. The product is multiple-use. It decreases waste in commercial procedures.

Chemical resistance is another vital function. The powder does not respond with acids or alkalis. It performs reliably in harsh environments. This prolongs the lifespan of equipment. It lowers maintenance prices.

Applications consist of ceramic coverings, metalworking, and accuracy molding. The powder works with advanced manufacturing techniques. It supports 3D printing of high-strength ceramic parts.

Personalized particle dimensions and structures are available. This satisfies certain project demands. The product is packaged in moisture-proof containers. It makes sure long-lasting storage security.

Industries like metallurgy, automobile, and energy depend on this product. It improves efficiency in high-stress processes. The mix of nano-scale innovation and zirconia’s residential or commercial properties makes it a top choice for demanding applications.

(Refractory Industry Nano Ceramic Zirconia Ceramic Powder Zirconium Dioxide Zro2 Zirconia Blasting Media)

Applications of Refractory Industry Nano Ceramic Zirconia Ceramic Powder Zirconium Dioxide Zro2 Zirconia Blasting Media

Nano ceramic zirconia ceramic powder (ZrO2) is a high-performance material widely utilized in the refractory market. It supplies extraordinary warm resistance, sturdiness, and chemical stability. These homes make it suitable for demanding commercial environments. The product’s high melting point (over 2700 ° C) makes sure integrity in extreme temperatures. It is commonly applied in heating system cellular linings, kiln elements, and steel spreading mold and mildews. These applications call for materials that endure long term direct exposure to warmth without breaking down.

In refractory coverings, zirconia ceramic powder functions as a thermal barrier. It protects surfaces from deterioration and wear in high-temperature procedures. This expands the life expectancy of industrial equipment. The nano-sized particles enhance layer harmony and attachment. This leads to smoother, more effective surfaces. Industries like steelmaking and glass production count on zirconia-based finishings to preserve operational performance.

Zirconia blasting media is another important application. It is utilized for surface prep work and cleansing in aerospace, auto, and electronics manufacturing. The product’s firmness and angular shape enable efficient removal of impurities without damaging substratums. Contrasted to typical media like sand, zirconia blowing up media lasts longer and creates much less waste. This reduces expenses and environmental impact.

The powder’s chemical inertness makes it suitable for usage in aggressive settings. It withstands reactions with acids, antacid, and molten steels. This is important in chemical handling and semiconductor production. Zirconia ceramics are likewise made use of in oxygen sensing units and fuel cell parts. Their ability to carry out ions at high temperatures sustains energy-efficient innovations.

Medical and oral areas gain from zirconia’s biocompatibility. It is utilized in implants and prosthetics due to its toughness and compatibility with human tissue. The material’s resistance to bacterial development enhances safety in medical care applications.

Nano ceramic zirconia powder is versatile. It attends to difficulties in high-temperature design, accuracy manufacturing, and progressed technology. Its flexibility across industries highlights its function as a cornerstone material in contemporary industrial services.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Refractory Industry Nano Ceramic Zirconia Ceramic Powder Zirconium Dioxide Zro2 Zirconia Blasting Media

What is Zirconia Ceramic Powder?

Zirconia ceramic powder is made from zirconium dioxide (ZrO2). It is a fine, white material. It handles high temperatures well. It resists wear and corrosion. Industries use it for tough environments like furnaces or engines.

Where is Zirconia Blasting Media used?

It is used for surface cleaning or coating prep. It works on metals, ceramics, or composites. It is common in aerospace, automotive, and tooling. It cleans without damaging surfaces. It lasts longer than sand or glass beads.

Why pick zirconia over other blasting media?

Zirconia is harder and tougher. It creates less dust. It cuts faster. It saves time and money. It does not break down quickly. It stays sharp for many uses.

Is zirconia blasting media safe?

It is non-toxic and chemically stable. Wear gloves and goggles when handling. Avoid breathing in fine particles. Use proper ventilation. Follow disposal rules for industrial waste.

How to choose the right zirconia powder?

Check particle size and purity. Smaller grains give smoother finishes. Higher purity improves performance. Match the grade to your project needs. Ask suppliers for technical details. Test samples before large orders.

(Refractory Industry Nano Ceramic Zirconia Ceramic Powder Zirconium Dioxide Zro2 Zirconia Blasting Media)

REQUEST A QUOTE

RELATED PRODUCTS

Zirconia Ceramic Guide Wheel, Precision Ceramic Parts,good Quality Zirconia Ceramic

Whole 0.2mm 0.3mm 3mm 10mm 12mm G10 Zirconium Dioxide Ceramic Grinding Ball Zirconia Beads

Ultra Precise Machining White Zirconia ZrO2 Tiny Ceramic Tube High End Zirconium Oxide Ceramic Small Components

Customized Zirconia Ceramic Engineering Processing High Quality Ceramic Processing

High Hardness Zirconia Ceramic Tube ZrO Ceramic Bush Sleeve