Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Zirconium Dioxide Ceramics

Zirconium Dioxide Ceramics, known for their toughness and ability to withstand extreme temperatures, are widely used in medical, automotive, and industrial applications due to their unique properties.

Features of Zirconium Dioxide Ceramics

Exceptional fracture toughness

High thermal expansion

Excellent resistance to wear and corrosion

Biocompatibility for medical implants

(ZrO2 Zirconia Ceramic Nano Zirconium Oxide Powder for )

Specifications of ZrO2 Zirconia Ceramic Nano Zirconium Oxide Powder for

ZrO2 Zirconia Porcelain Nano Zirconium Oxide Powder is a high-performance product. It is made use of commonly in sophisticated commercial applications. The powder consists of ultrafine nanoparticles. The average bit dimension ranges from 20 to 100 nanometers. This makes sure a high surface area. It improves reactivity in chemical procedures. The purity degree exceeds 99.9%. This makes it ideal for accuracy uses. It is without heavy metal impurities. The powder has remarkable thermal stability. It holds up against temperature levels approximately 2400 ° C. This stops architectural degradation under severe heat. The product shows low thermal conductivity. It is optimal for thermal obstacle coatings. The mechanical toughness is outstanding. It stands up to cracks and put on. This prolongs the life expectancy of parts. The firmness is comparable to ruby. It keeps efficiency under high tension. The chemical resistance is solid. It does not react with acids or antacid. This ensures reliability in destructive settings. The powder is chemically inert. It continues to be steady in the majority of solvents. The phase structure is customizable. It can be monoclinic, tetragonal, or cubic. This relies on processing conditions. Each stage uses one-of-a-kind benefits. Monoclinic frameworks improve durability. Tetragonal phases boost fracture resistance. Cubic forms are utilized in oxygen sensing units. The powder works with sintering processes. It achieves high-density ceramic items. Applications include aerospace components. It is used in jet engine coverings. Clinical implants take advantage of its biocompatibility. Oral crowns use this product for durability. Electronic devices depend on it for shielding layers. It works as a stimulant assistance in chain reactions. The powder is included in compounds. It boosts toughness without adding weight. Handling requires standard safety measures. Avoid breathing or direct call. Storage space problems must be completely dry and cool. Dampness impacts performance. This product meets worldwide high quality criteria. It is examined for consistency. Customized particle dimensions are available. Mass orders can be tailored to requirements. Technical support is attended to integration. The powder is a cost-efficient service. It lowers upkeep requirements in rough conditions. Industries pick it for dependability. Efficiency is validated in real-world situations.

(ZrO2 Zirconia Ceramic Nano Zirconium Oxide Powder for )

Applications of ZrO2 Zirconia Ceramic Nano Zirconium Oxide Powder for

ZrO2 zirconia ceramic nano zirconium oxide powder is a flexible product with lots of useful uses. It is widely made use of in dental porcelains. The powder assists create solid, natural-looking dental crowns and bridges. It is biocompatible. It withstands wear. It matches the appearance of real teeth. Clinical implants gain from this material. Its high strength and sturdiness make it suitable for hip substitutes and bone screws. The body endures it well. It lasts long in demanding atmospheres. Industrial applications prevail. The powder is used to make reducing tools, bearings, and engine components. It handles heats. It withstands corrosion. It decreases rubbing in machinery. Electronics manufacturers use ZrO2 in sensing units and fuel cells. The material carries out ions at heats. This improves the performance of solid oxide fuel cells. It maintains elements in oxygen sensing units. This ensures accurate analyses in auto exhaust systems. The powder is beneficial in coverings. It shields surface areas from warm, abrasion, and chemicals. Aerospace elements use these finishings. Turbine blades last much longer. They execute better under tension. Stimulants count on nano zirconium oxide. It accelerates chain reactions in refining and contamination control. Its surface assists damage down damaging materials. Fashion jewelry manufacturers make use of ZrO2 for synthetic gemstones. The powder creates crystals that resemble rubies. These rocks are resilient. They cost less than natural treasures. Researchers check out brand-new usages. ZrO2 reveals promise in batteries and solar batteries. It might enhance power storage space. It may improve photovoltaic panel effectiveness. The powder’s small particle size permits specific control in manufacturing. This brings about far better performance in end products. Industries select ZrO2 for its flexibility. It solves issues in healthcare, engineering, and technology. Its special homes make it a vital material for advanced applications.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of ZrO2 Zirconia Ceramic Nano Zirconium Oxide Powder for

1. What is zirconia ceramic nano zirconium oxide powder? This is a high-performance material made of tiny zirconium dioxide particles. The particles are nanometers in size. It has high strength and heat resistance. It works well in extreme conditions. Industries like aerospace and medical devices use it often.

2. Where is this powder used? It is used in many areas. Dental implants and joint replacements use it because it is biocompatible. Electronics use it for insulation. Industrial coatings use it for wear resistance. It is also added to ceramics to improve durability.

3. What makes this powder better than regular ceramics? It has a finer structure. This improves hardness and toughness. It resists cracks under stress. It handles high temperatures without breaking. Chemical stability prevents corrosion. These traits make it last longer in tough environments.

4. Is this powder safe to handle? Wear gloves and masks when handling it. Dust can irritate lungs or skin. Work in well-ventilated areas. Follow safety guidelines from the supplier. Store it in sealed containers away from moisture.

5. Can I buy different particle sizes? Yes. Particle sizes range from 20 nanometers to several microns. Smaller particles offer higher surface area for reactions. Larger ones are easier to process. Custom sizes are available for specific needs. Contact the supplier for details.

(ZrO2 Zirconia Ceramic Nano Zirconium Oxide Powder for )

REQUEST A QUOTE

RELATED PRODUCTS

Ultrapure 99% Nano Zirconium Oxide Powder Zirconia Nanopowder ZrO2 Nanoparticles for Ceramics

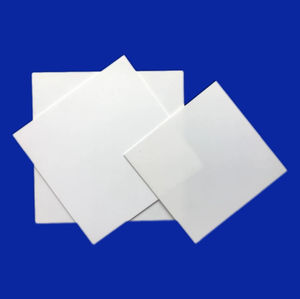

Very Thin Zirconia Black Ceramic Sheet Substrate Surface Polishing Round Zirconium Oxide Ceramic Plate

Factory Supply 99% ZrO2 Nano Zirconium Dioxide / Zirconium Oxide / Zirconia Nanoparticles CAS 1314-23-4 Ceramic Powder

Stabilized Zro2 Zirconia Zirconium Oxide Ceramic Sheet for Sinter

ZrO2 Zirconia Ceramics Rods Bars Raw Material For Industrial Medical Machining